Frequently Asked Questions

PLEXUS® Questions:

7 months at 24°C for most 1:1 mix ratio formulations, and up to 13 months for many 10:1 mixed systems. For specifics, please refer to the Technical Data Sheet for each product.

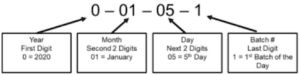

For many products, this will be part of a six-digit lot number on the packaging that reads as follows:

For the first format (commonly found on Plexus and Devcon products), use lot #001051 as an example:

• The first digit is the year after 2020, so 0 indicates 2020

• The second and third digits are the month, so 01 indicated January

• The fourth and fifth digits are the date, so 05 indicates the 05th

• The sixth number is the batch number, so 1 indicates batch #1

The product information you are looking for can be found on our Safety Data Sheets Page.

These specifications can be found on our Technical Data Sheets Page.

65 to 78 Shore D. The majority of Plexus products tend to be approximately 72 Shore D.

If frozen, Plexus products will become very rigid, but still pliable. If you allow frozen product to heat back up to room temperature, nearly all Plexus materials will return to their original form and perform as expected. As a result, they may be used. If a product does not look smooth after recovering, it is not recommended to be used without first testing to ensure a proper cure.

Yes, for a short period of time. The product’s catalyst, which is a peroxide, degrades with time and temperature. So, the warmer you store it, the shorter it will last. Please see the specific product’s Technical Data Sheet for recommended storage conditions.

You are likely using the product within a joint larger than it was designed for, or you have a large amount of squeeze-out exceeding the gap capability of the particular Plexus product. Please see the product’s Technical Data Sheet for recommended gap sizes.

Try to minimize your bond line gap. A narrower bond line will not only help save on adhesive and cost but will lower your product’s weight and produce a higher quality final part.

PC120 is the recommended cleaner/conditioner, but Acetone, Isopropyl Alcohol, Toluene, MEK and

some Terpene’s are all compatible cleaners with PLEXUS®.

To reduce or eliminate this phenomenon, try reducing your bond line gap. This will create a lower reaction temperature, leave less product to shrink, and lower your overall part cost.

If this is does not reduce or eliminate this effect, please see our product selection for a lower shrink product or contact our Technical Services department for assistance.

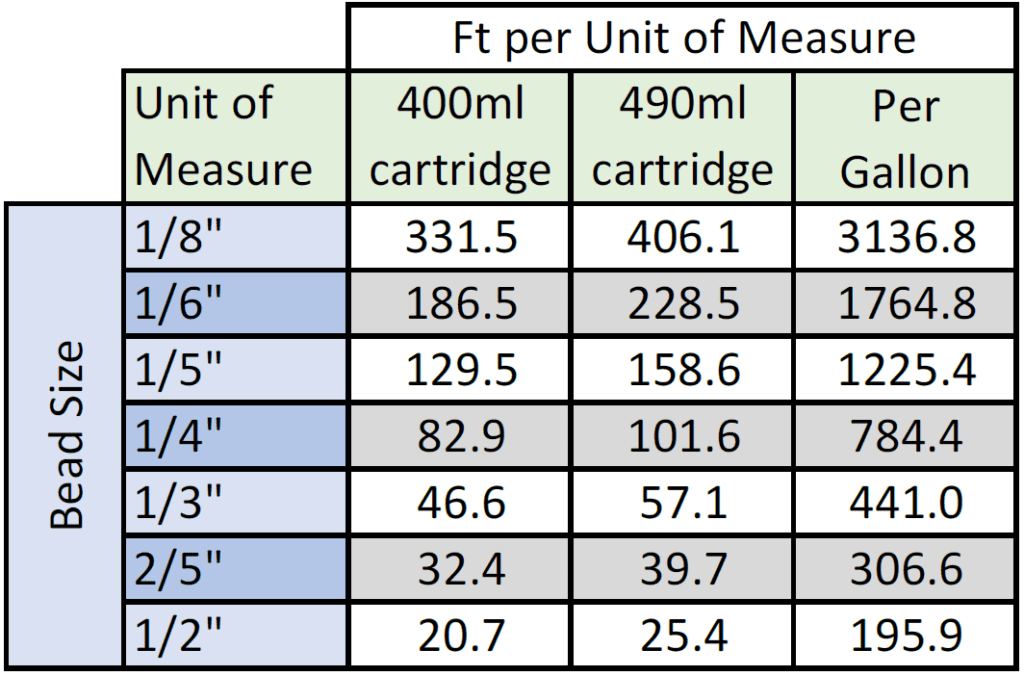

The Table below is an approximate based on a rounded bead size as shown and is only a guide. Amounts for an application should be calculated by volume

based on bead size and gap.

General Questions:

The product information you are looking for can be found on our Safety Data Sheets Page.

These specifications can be found on our Technical Data Sheets Page.

Products can be purchased through our distributor network. Click here to find the distributor closest to you.