ITW Performance Polymers Industrial Grouts, Polymers, and Foundation Systems in Action

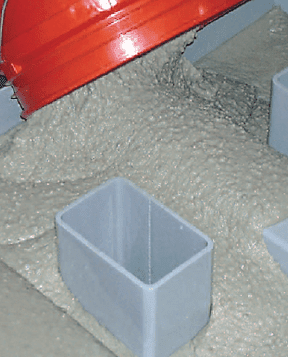

The Chockfast® and Escoweld® epoxy grouting systems have been specifically engineered to provide the optimal performance and reliability for use under critically aligned equipment.

The right grouting system, as part of a well engineered equipment system, can provide years of cost-effective, reliable performance. Selecting the right grouting system is as simple as having an understanding about what the ITW Performance Polymers Chockfast and Escoweld epoxy grout systems provide.

Chockfast has a long successful history in the natural gas transmission industry. The “Chockfast System” supports more horsepower than all other systems combined. Escoweld enjoys an excellent reputation in the world of pumps with its improved chemical resistance to many industrial chemicals and its vibration dampening capability.

From thin pour epoxy chocks to large foundation repairs, ITW Performance Polymers has the properly engineered system for your critical equipment needs.

Get information on our complete line of high performance epoxy grouting systems.

Proven Solutions

COMPRESSORS

When you need a foundation that won’t shake to pieces…

Reciprocating compressors present the single most common application for epoxy grouts. Because of the vibration, chemical attack, field installation issues and reliability concerns, most manufacturers prefer a solid, reliable foundation under their equipment. Decades of experience has shown that when performance of the foundation system is critical to the overall function of the equipment, polymer systems provide the best solution to the long-term performance of the overall package.

CRANE RAILS

Heavy loads require a heavy-duty foundation…

Setting crane rails is greatly simplified by using epoxy grout as opposed to steel or concrete. With higher compressive strengths and resistance freeze thaw cycles polymer products are far superior to the cement grout that is normally used for setting these rails. Most of the time the grouts will replace both the cement grout and the leveling plate found under the rail. Not only does the epoxy support the rail evenly it seals the underside of the rail from corrosives and dirt.

PIPE SUPPORTS

Because remote pipe support locations are no place to have a failure…

Epoxy pipe supports or shim blocks are the answer to your pipe inspection problems. They eliminate pipe support corrosion, fretting and vibration associated with the higher costing steel supports. They require no maintenance and are available in two different styles; wedge shaped or rounded. Both models are fully adjustable and will fit just about any size pipe. Made from the same three component epoxies used in the rebuilding of pipe piers, they are easily removed for pipe inspection and comply with DOT Federal regulations.

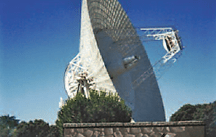

SATELLITE DISH FOUNDATIONS

When you are aiming at a target a million light years away, you’d better shoot straight…

Permanent, accurate alignment of multi-million dollar satellite dishes is just one example of where polymer grouts outperform the alternatives. Mid-service regrouting of critical equipment because of foundation degradation is just not an alternative in most of these applications. The stability, vibration attenuation and ease of installation of our foundation systems make epoxy grouts an easy decision when long-term performance is the deciding factor.

PULP & PAPER

When the environment is corrosive, why use a foundation that crumbles…

The pulp and paper manufacturing environment has always presented one of the most difficult settings for the designer of equipment foundations. The constant chemical attack, the high levels of vibration and the minimal “down time” requirement of this industry have always been issues that polymer bases can easily solve. Quick cure times and high chemical resistance are inherent properties of our systems, making them ideal solutions to the never-ending equipment problems caused by foundation failure in these situations.

POWER/TURBINES

When turbines cost millions of dollars, why skimp on the foundation…

Power generation has an inherent need for reliability. Equipment costs are high and shutdown/downtime costs are even higher. The added reliability of polymer bases can only increase the already high level of dependability designed into these systems. Accurate alignment, a decrease in overall vibration and the longer equipment life provided by a polymer base only add to the already high level of sophistication of these power plants.

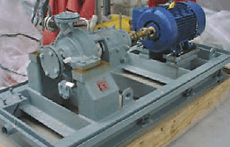

OPEN DECK GROUTING/PUMPS

Open deck grouting provides a new solution to an old problem…

By utilizing a wider, stiffer flange and support mechanism in conjunction with epoxy grout, it is now possible to level the base without removing the pump and motor. The rigidity of the base prevents any twisting or warping during shipping and handling. Setting, leveling to grade, rough alignment, and forming for first pour is possible in one day and can be done in the shop instead of a difficult field environment. In these installations the top of the polymer becomes the actual top of the baseplate.

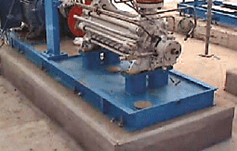

SKIDS

Because you don’t want your equipment to “skid” to a halt…

More and more equipment today is being mounted on rails or skids. Because the design varies from unit to unit and there is no set guideline for installation, epoxy grouts should always be used to minimize the vibration levels, decrease the downtime and maximize the life cycle of the equipment mounted on those skids. With minimum clearance and ever bigger skids ITW Performance Polymers has the right epoxy grout for any installation, permanent install, leased unit or temporary problem solver.

Chockfast delivers proven results in the toughest industrial environments. Now take action and choose the Chockfast brand for your application. Contact the Technical Services team to see which product will benefit your team.