WELD REPLACEMENT

ARC WELD REPLACEMENT

A weld is essentially a localized heating process that fuses metal together when they have similar melting points. The quality of a weld can vary, as it takes quite a bit of skill to perform. Plexus structural adhesives are considered as a superior metal glue alternative to welding. If a welded joint is on thin metals or requires post processing such as grinding, both the weld and the grinding often cause distortion or scaring. In these situations, Plexus structural adhesives are used to eliminate such problems.

Weaknesses of Welding Assemblies:

- Welding takes considerable skill to do well and requires costly labor

- May require good surface preparation

- Often requires post processing such as grinding

- Thin metals and dissimilar thickness metals are difficult to weld

- Cannot join dissimilar metals or materials

- It can remove galvanized and other protective coatings and lead to areas of corrosion

- Heat affected zones (HAZ) can reduce the strength of the sheet metal

BENEFITS OF PLEXUS BONDED ASSEMBLIES

- Easy to use and lower cost of assembly

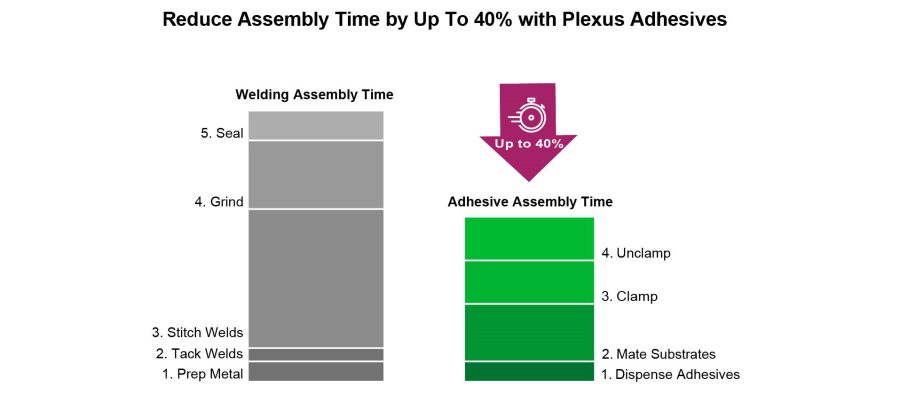

- Plexus can reduce amount of time to assemble

- Use less expensive labor

- Eliminate post processing like grinding

- Eliminate weld print though or burn through and distortion

- Offer enhanced design flexibility and freedom

- Can join dissimilar material (no galvanic corrosion)

- Can connect hard to reach places

- Enables thinner gauge material

- Improve durability

- No heat affected zones (no HAZ)

- High fatigue resistance

- Sealing and gap tolerances

- Will join and seal in one step

- Acts as a “liquid shim” which can handle gaps and larger tolerances

FAST & EASY TO USE

Laying down a bead of glue and putting two products together is considerably easier than creating consistent manual welds. Plexus adhesives are easy to use, forgiving to off ratio mixing, bond through light metal oil and can eliminate grinding and/or sealing downstream. Here is an example of how Plexus can be used as a weld glue replacement.

ELIMINATE WELD HEAT DISTORTION

Plexus structural adhesives allow for gluing metal without excess heat that leads to print through. There is a large benefit when using Plexus adhesives to join metals of different gauge thickness; Plexus will not cause any warping, which saves considerable time downstream to maintain.

REDUCING CORROSION

Not only does Plexus bond and seal, but it provides a non-conductive layer between metals. This helps eliminate potential corrosion. Welding galvanized or Galvanneal metals will destroy the protective layer, leading to higher risk of rust and corrosion and warranty claims.

Plexus has a range of products that are primer-less to galvanized and that can bond metals as is. Contact our technical service team to learn more about the Plexus range.

SWITCHING FROM WELDING TO ADHESIVES

Thinking about switching from welding to adhesives? Here are some key questions to help identify if an application is right for Plexus metal bonding adhesives:

- Is there sufficient surface area for the adhesive?

- Would I eliminate post processing such as grinding or sealing?

- Does my current welding process cause heat distortion?

- Is the welded joint hard to reach, such as above head or inside closed areas?

- Are there welded assemblies that take significant time?

- Are there areas welded to seal an area and not for strength?

Contact us to learn more about which Plexus adhesive is most suitable for your project.

CLAMPING

Plexus adhesives are engineered to not only be thixotropic (non-sag), but also to spread very easily. Best practice is to ensure even clamp pressure across the bondline, sufficient to prevent joint separation until a defined handling strength is achieved.

Here are some tips for clamping:

- Only 0.75 PSI – 1.75 PSI pressure is needed to spread out most Plexus products

- For flat sections, bar clamps help provide even pressure across the bond area

- Strategically placed mechanical fasteners can be used to help move products down line faster

- Select Plexus branded products contain glass beads to prevent over clamping

- Engineered standoffs or gaps directly on the part can help contain the adhesive and guarantee certain bond gap

SURFACE PREPARATION FOR ADHESIVES

Plexus adhesives are engineered to be very robust with minimal to no surface preparation.

- Thermoplastics – A simple dry rag wipe (to remove any dust) is sufficient in most cases

- Composites – Depends on the chemistry, most RTM composites can be bonded after a dry rag wipe or solvent wipe. Other composites might need light abrading

- Raw Metal – Plexus has a line of primer-less to metal adhesives, which can often bond after a solvent wipe. For heavily oxidized metal, abrasion and solvent wipe is recommended.

- Coated Metals – Can often be bonded as is after a wipe to remove any dust.

Testing the exact material is important to any successful project. Contact us to learn more about Plexus adhesives that can best address your project needs.

JOINT DESIGN

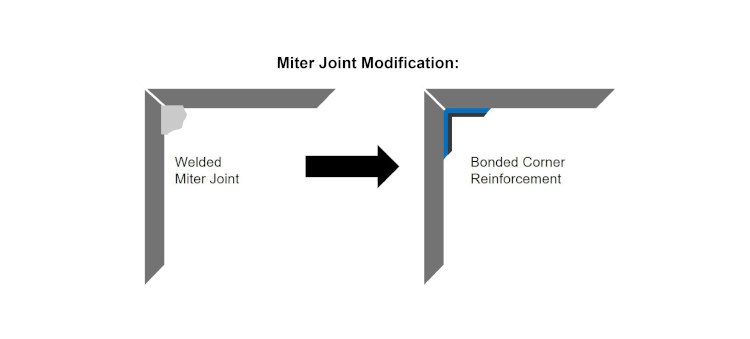

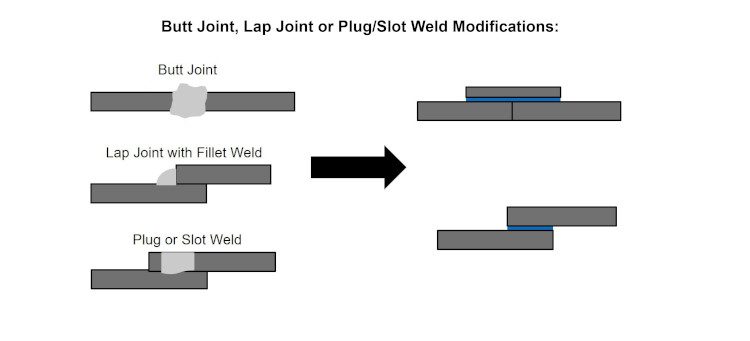

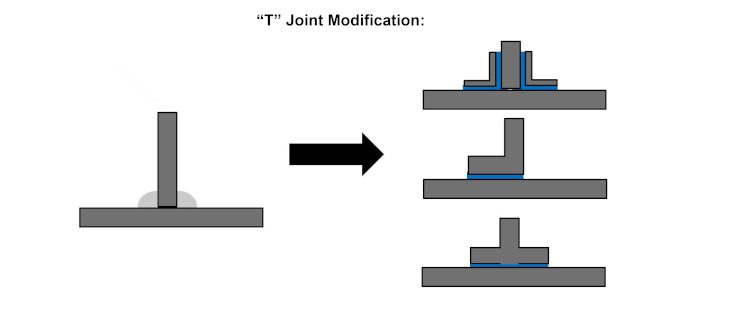

With the right design, using Plexus adhesives to bond metal can help outperform welding. An adhesive is not always a direct replacement for a weld, and design considerations should be taken into account.

Below are some common examples of how to modify a welded joint into and adhesive bonding joint design:

Want to switch from mechanical fasteners or welding to a strong metal glue, contact our Technical Service Department today to get started.

SEE HOW EASY IT IS TO APPLY PLEXUS ADHESIVES

Seeing is believing. Watch this short video to see how easy it is to apply Plexus adhesives.