Polyamide, sometimes called Nylon, is a semi-crystalline thermoplastic used in several different industries, particularly in high temperature applications. Polyamides can be molded “neat” or as a filled system to achieve different properties.

Historically, finding an adhesive to glue polyamide was difficult without extensive surface preparation. Many manufacturers have asked the Plexus® team for fast, room temperature curing solutions to bond polyamide to aluminum and other metals (glue nylon to aluminum).

Surface Preparation:

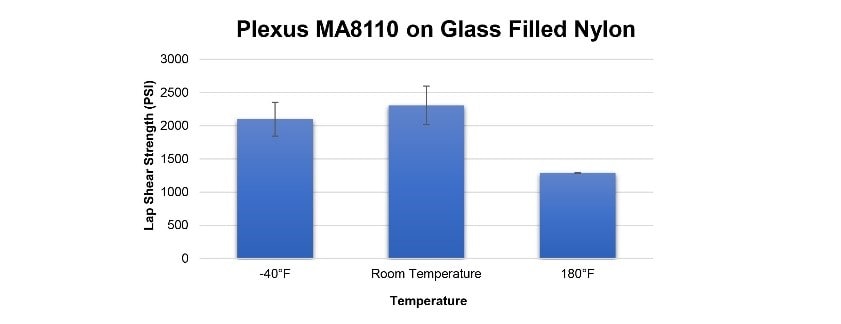

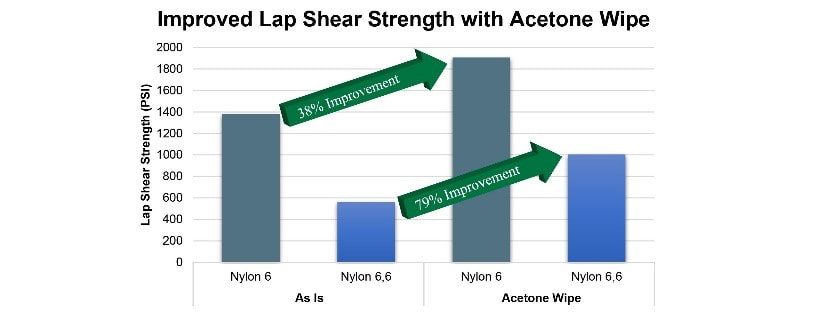

Older chemistries often required mechanical abrasion, flame, or plasma treating to get good adhesion to polyamides. The team at Plexus introduced the new 8100 series product of structural adhesives that offer primerless adhesion to polyamide substrates. These adhesives offer best in class bonding polyamide as received and offer great adhesion strength at high operating temperatures of around 180°F (82°C). There are many different grades, fillers, and mold releases used with polyamides, so please contact the Technical Service team at ITW Performance Polymers for solutions.

Potential Uses:

Polyamide, or nylon, can be molded into many different parts and geometries. Molded parts or thermoformed parts of glass filled polyamide are being used to reinforce metal structures at lower cost and with considerable savings. This is one of the reasons Plexus adhesives are used to bond polyamide to aluminum. Wire clips, brackets, and other parts made with polyamide eliminate the concern with corrosion as compared to their metal counterparts. These small parts require a fast adhesive that can cross bond polyamide with multiple other substrates like composites, other plastics, or metals.

For help picking the right industrial adhesive for bonding nylon (polyamide), reach out to our Technical Services team for the expert support you need.

By: Max VanRaaphorst, Business Development Manager and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.