One of the most common questions people ask about structural adhesives and bonding applications is: Will it be strong enough?

Almost always, the answer is – probably, yeah, but there’s a lot more we need to know before we can be sure. Most of the time, strength is an important factor in choosing an adhesive solution…but it’s not the only thing.

Properties

Plexus® brand adhesives are all tested for their inherent mechanical properties (tensile, modulus, and elongation), as well as their performance on key substrates such as: carbon & stainless steel, aluminum, galvanized steel, fiberglass, thermoplastics, acrylics, coatings, and others. They generally have very high strength, and due to their core-shell technology, exhibit toughness and fatigue resistance that is market-leading. Plexus adhesives offer a range of strength properties that go from our Plexus-H4110 SMP-Epoxy hybrid elastomer at 6.5MPa of tensile, to high-strength MMA & 2-component Polyurethanes, with tensile strengths greater than 20MPa.

Why do structural adhesives have different strength properties?

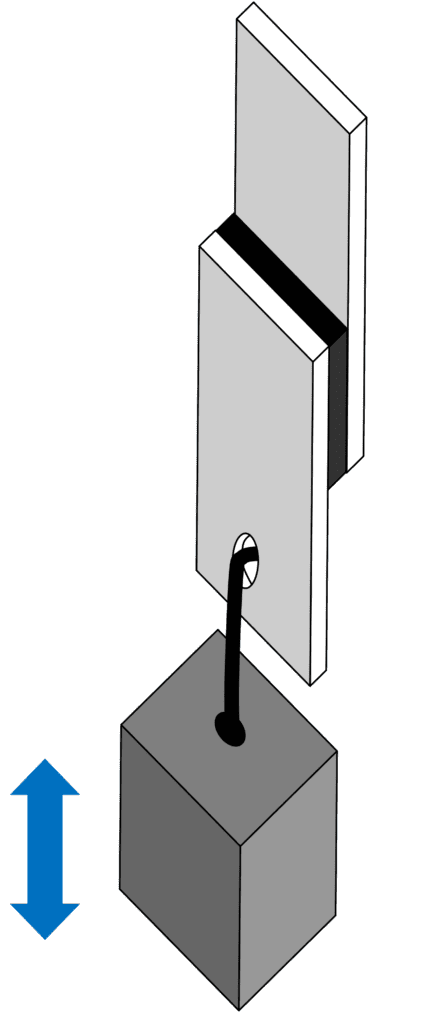

Structural adhesives are formulated with a range of strength properties for several reasons. In each case, the target application is an important part. The strength of an adhesive is often closely related to its ability to deform under stress. Usually, higher strength materials will deform less. However, many applications require this movement, whether due to temperature cycling, or stresses caused by forces on the assembly itself – like when a bus goes around a tight corner. These are dynamic loads. In this case, a lower strength or modulus may be desirable.

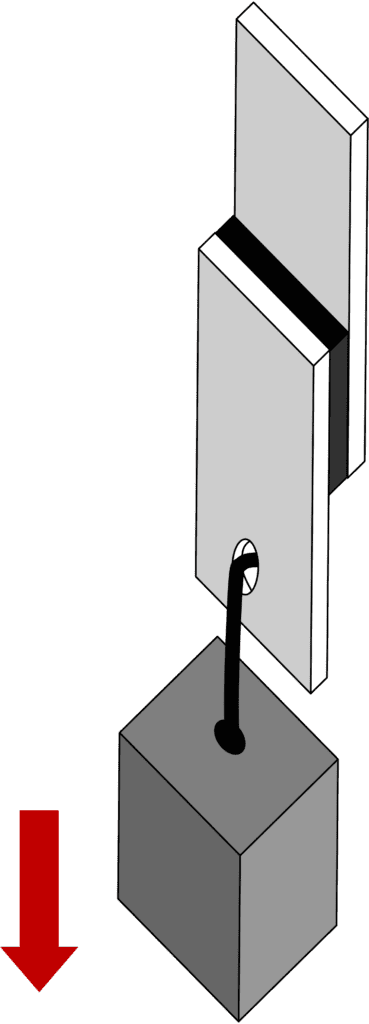

However, if the application is to support a large weight in a relatively constant position, a higher strength material is required, so that over long periods of time, the adhesive is capable of handling the force from gravity. This is a static load.

What if you need both?

Thankfully, this is where our Plexus chemists and technical service engineers help. Over the many years of experience, Plexus has developed products with specialized properties that can give the right amount of strength & flexibility, with primerless adhesion. We can also help to define your application, so that the right amount of adhesive is going to the right place.

Do you have questions about strength, modulus, and elongation, static & dynamic loads or bonding in general? Contact Technical Support for more information.

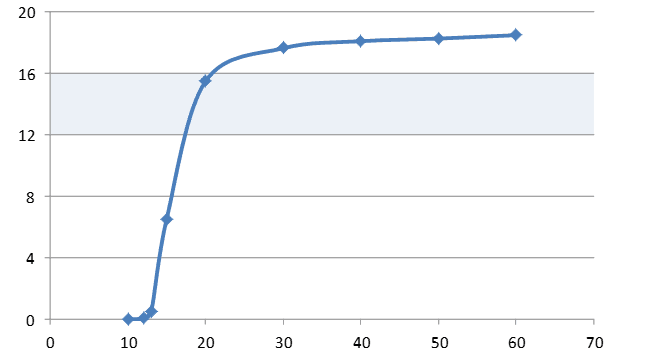

X axis = time

Y axis = lap shear strength (MPa)

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my! and What is fixture time anyway?.

For more information like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.