THE CHOCKFAST ADVANTAGE

For Precise and Permanent Alignment of all Machinery

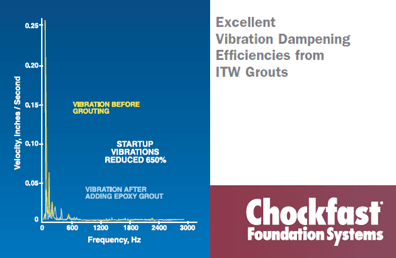

- Excellent Vibration Damping

- High Compressive & Bond Strengths

- Superior Resistance to Shrinkage, Fretting and Shear Loads

- Serviceability within 24 Hours

- Global Representation

Why choose Epoxy Grout…

If you are interested in…

- Increasing Equipment and Foundation Service Life

- Lowering Equipment Operating Costs

- Increasing MTBF

…the choice for your next installation

is ITW Performance Polymers

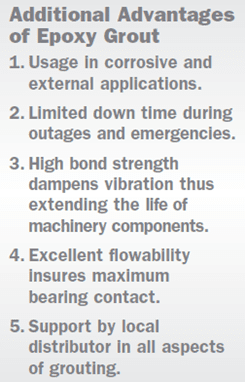

ITW Performance Polymers epoxy grout systems provide all of the advantages necessary for superior performance including fast, convenient installations; precise, reliable alignment; resistance to thermal growth under hot-running machinery; rapid curing with negligible shrinkage; and maximum versatility for dependable solutions with the most difficult installation problems.

There is an ideal epoxy product for each grouting or chocking application. ITW Performance Polymers has earned an unmatched reputation for reliability with major gas pipelines; chemical, petrochemical and refining complexes; power facilities; mining operations; manufacturing; engineering and design organizations; and industrial constructors worldwide.

Which product is right for you?

ITW Performance Polymers gives you superior choices with Chockfast® Foundation Systems and Escoweld® Industrial Grouts & Polymers

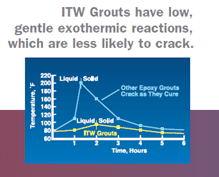

A 3-component, 100% solids, deep-pour, multi-purpose epoxy grout for fast, permanent alignment of reciprocating equipment. Also used as a polymer concrete for fast reconstruction of worn or damaged foundations. Chockfast Red provides excellent vibration damping for static and dynamic loads, while its gentle exothermic cure allows for single pours from 2” to 18” (51 mm to 457 mm). | |

A 3-component, 100% solids, enhanced flow, epoxy grout, Chockfast Red SG is used to grout large machinery applications where a lighter consistency material is required and clearances from 1” to 4” (25 mm to 102 mm) are typical. | |

A versatile 3-component, 100% solids, epoxy optimized for pumping and flow properties. Capable of low clearance, large area pours. Pump transfer results in high discharge volumes. Hose delivery overcomes challenges of difficult to access areas such as large skid packages, elevated structures, or congested areas. Standard kit provides desired results, no need to adjust aggregate levels. | |

A 3-component, 100% solids, deep pour, epoxy grout; ESCOWELD® 7505/7530 offers many benefits designed to simplify equipment installation while providing excellent chemical resistance and vibration damping for pumps and other critically aligned rotating equipment. Pours from 2” to 18” (51 mm to 457 mm) are typical. ESCOWELD® is available in North America only. | |

A 2-component, low viscosity, structural epoxy “chock”, or “poured shim” with variable hardener ratios options. Replaces tediously fitted steel chocks or shims. Assures intimate contact with machined or un-machined equipment bedplates. Virtually 100% effective bearing underneath supported equipment. Normally poured in thickness’ of 1/2” to 4” (12 mm to 100mm) | |

A 2-component, 100% solids, highly flowable, thin pour “chock” or “poured shim”; designed to maintain proper alignment and support of machinery and equipment. Able to withstand severe industrial environments with a high degree of both physical and thermal shock resistance. Normally poured in thicknesses of 1 – 1/4 ” to 2 – 1/2” (30 mm to 65 mm). | |

A 2-component, highly flowable, thin pour “chock” or “poured shim”; designed to maintain proper alignment and support of machinery and equipment. Able to withstand severe industrial environments with a high degree of both physical and thermal shock resistance. Normally poured in thicknesses of 1 – 1/4” to 2 – 1/2” (30 to 65 mm). |