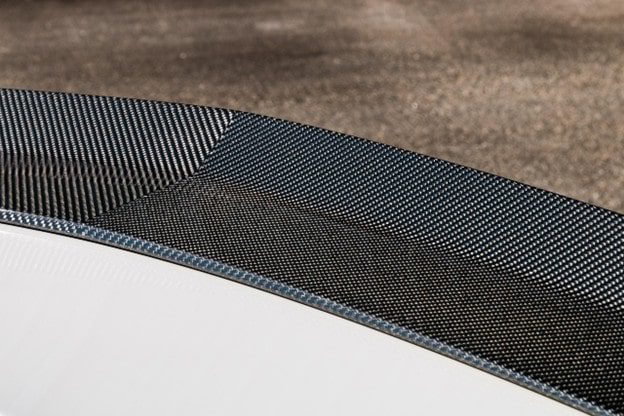

Carbon fiber reinforced plastic (CFRP) is a composite material known for its high strength-to-weight ratio, making it ideal for automotive applications. CFRP bonding of auto parts requires an adhesive that can withstand the demanding stress and strains of automotive use.

High elongation epoxy and methyl methacrylate (MMA) adhesives are two popular choices for these applications as they are high performance automotive adhesives and a flexible epoxy. This article explores the benefits and applications of a carbon fiber reinforced plastic adhesive used in bonding CFRP auto parts with Devcon HP250 and Plexus MA425.

High Elongation Epoxy

High elongation epoxy adhesives such as Devcon HP250, are structural and designed to provide strong, durable bonds while accommodating the flexibility and movement of bonded parts. These adhesives are particularly useful in automotive applications where parts are subjected to dynamic loads and thermal expansion.

Advantages of High Elongation Epoxy:

- Flexibility and Durability: High-elongation epoxies can absorb and distribute stress, reducing the risk of bond failure under dynamic loads[1]. This makes them ideal for bonding CFRP parts that experience significant movement and vibration.

- Thermal Resistance: These epoxies can withstand high temperatures, making them suitable for use in engine compartments and other high-heat areas[1].

- Chemical Resistance: High elongation epoxies are resistant to automotive fluids, ensuring long-term durability in harsh environments[1].

Applications in Automotive Industry:

- Body Panels: High elongation structural epoxies are used to bond CFRP body panels to metal frames, providing a strong, lightweight connection that enhances vehicle performance and fuel efficiency[1]. Structural bonding, in particular lightweight material bonding, is enhanced when usings CFRP adhesives solutions.

- Chassis Components: These adhesives bond CFRP components in the chassis, improving structural integrity and reducing weight[1].

- Interior Parts: High-elongation epoxies are also used for bonding CFRP interior parts, such as dashboards and door panels, where flexibility and durability are essential[1].

Methyl Methacrylate Adhesives

Methyl methacrylate (MMA) adhesives are two-part reactive adhesives known for their fast curing times and strong bonds. They are particularly effective for bonding dissimilar materials, such as CFRP to metals or other composites.

Advantages of MMA Adhesives:

- Fast Curing: MMAs cure quickly at room temperature, allowing for rapid assembly and production[2].

- High Strength: These adhesives provide strong, durable bonds that can withstand high loads and stresses[2].

- Versatility: MMAs can bond a wide range of materials, including metals, plastics, and composites[2].

Applications in Automotive Industry:

- Exterior Panels: MMAs are used to bond CFRP exterior panels to metal frames, providing a strong, lightweight connection that enhances vehicle performance[2].

- Structural Components: These adhesives bond CFRP structural components, such as roof panels and side skirts, to metal or composite frames, improving overall vehicle rigidity and safety[2].

- Battery Enclosures: In electric vehicles, MMAs bond CFRP battery enclosures to metal frames, ensuring a strong, durable connection that can withstand the stresses of daily use[2].

Conclusion

Both high elongation structural epoxy and methyl methacrylate adhesives offer significant advantages for bonding carbon fibre reinforced plastic auto parts. High elongation epoxies provide flexibility and durability, making them good options for dynamic and high temperature applications. MMAs offer fast curing times and strong bonds, making them ideal for a wide range of automotive applications.

By leveraging both types of technologies, manufacturers can create lightweight, durable, and high performance vehicles that meet the demands of modern automotive engineering.

Links to Source Materials

- Joining & Bonding of Composite Parts – The Structural Adhesive Advantage

- How to Bond Carbon Fiber – Permabond

- Adhesive Bonding of Carbon Fiber Reinforced Plastic to Advanced High Strength Steel

- Methyl Methacrylate Adhesives (MMAs): Applications, Pros, & Products

- A User’s Guide to Methyl Methacrylate Adhesives

- Exploring Methyl Methacrylate Adhesives (MMAs) – MPI Matco

If you need any more information or further assistance, feel free to ask!

References

[1] Joining & Bonding of Composite Parts The Structural Adhesive Advantage

[2] Methyl Methacrylate Adhesives (MMAs): Applications, Pros, & Products

By: Kry Wesselink, Product Manager EMEA

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more information like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.