Learn How to Repair, Rebuild & Protect Your Equipment with the Devcon DFense Blok Wear Resistant Coating

Founded in the 1950s, Devcon was formed to develop wear coating products, replacing welding with safer alternatives. Since that time, the Devcon brand has grown to offer numerous superior wear and abrasion resistant coatings that span across multiple industries. As Devcon continued to produce many wear coatings, one of the top developments was Devcon DFense Blok, the most durable impact resistant product able to protect from abrasive wear.

Devcon DFense Blok stands out in the industry as a high-performance, impact-resistant coating designed to protect equipment from impact and abrasive wear. Its durability is evident, as it absorbs impacts up to 7 times better than ceramic tile, making it an excellent choice for harsh environments.

Key Features:

- Reliability: Your team can rely on Devcon DFense Blok as it’s an extremely durable wear coating that performs superiorly in dry environments.

- High Durability: Provides long-lasting protection against wear and repeated impact.

- Surface Wetting Agent (SWA): The bright orange Devcon DFense Blok Surface Wetting Agent (SWA) enhances product adhesion and simplifies surface preparation.

- Versatile Applications: Ideal for both dry and wet environments, ensuring broad usability across various industries.

Devcon DFense Block Wear Resistant Coating Applications

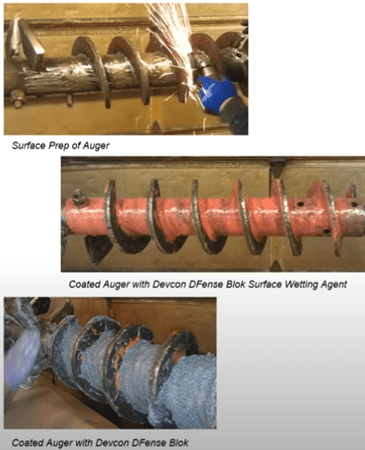

- One example of an application that benefits from Devcon DFense Blok coating is an auger. In one scenario, the customer wanted to minimize damage by applying our most durable wear coating product.

As you can see on the top photo, they used a grinder to rough up the metal surface of the auger. They then applied the Devcon DFense Blok Surface Wetting Agent over the surface to enhance product adhesion. Next, they applied a full coat of the Devcon DFense Blok. This simple assembly provides long-term protection extending the life of the product.

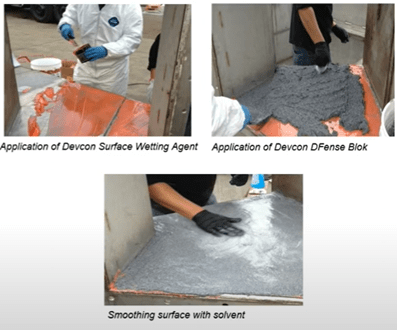

2. Our next example is a power plant chute. In this scenario, the customer knew that they receive high amounts of wear from particulates running through their chutes. Therefore, they precoated the equipment prior to assembly.

As you can see, the bright orange of the Surface Wetting Agent provides a clear view that ensures the applicator covers the full area, even in dimly lit areas. Once applied, the wear coating product is smoothed with solvent, providing a smooth surface. Read the case study.

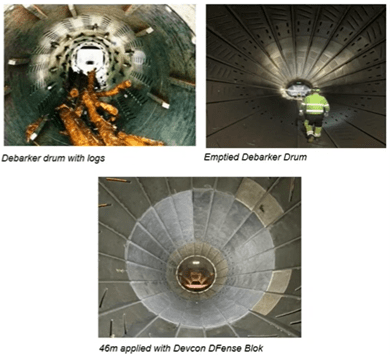

3. We now go to a very high wear application. These are large debarker drums that are used in a pulp & paper mill. This debarker drum takes the logs at the origin of the process and removes the bulk from the logs as they move through the process. You can see with the photo on the right the size and scale of the drum.

The customer was concerned with the amount of wear that the drum experienced on a regular basis. They tested our wear coating product against a competitor on a test patch of the drum for 6 months. During the test it was found that the Devcon DFense Blok saw almost no wear, whereas the competitive material saw extensive wear. The customer went ahead and approved to apply the DFense Blok for the next 46m on the drum.

The Devcon Solution

Devcon’s Wear Guard family of industrial strength epoxy coatings offer wear coating products that allow you to rebuild, repair, & protect equipment. These high performing and easy to apply products provide solutions in the toughest conditions. Not only are these durable and innovative products, but they come with a dedicated technical and customer support team who are ready to assist with choosing the correct product for your unique situation. Our global manufacturing & supply networks ensure that ITW Performance Polymers can provide products to you in a quick manner. With over 70 years of proven solutions, we are confident that Devcon can provide you with a answer to your maintenance needs.

Check out the other Devcon® 101 Series blog posts:

- Devcon® 101 Series: Fast Curing, Wear Resistance with Devcon Coatings

- Devcon® 101 Series: Elevated Temperature Wear Resistant

- Devcon® 101 Series: Wear Resistance with the Devcon Wear Guard™ Family

By: Tony Mell, N.A. Sales Director and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Durability With Devcon® Protective Coatings: Proven In Multiple Industries and The Top Four Types Of Wear Impacting Industrial Equipment.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.