If you can build it, you will inevitably need to fix it.

One of the first things that needs to be considered when designing a product is how that product will be maintained or repaired. As we become more conscious about sustainability, including the circular economy, recycling & upcycling, and “right to repair” regulations that are becoming increasingly commonplace, we should ask questions about our joining methods before we finalize our designs.

Adhesives & Repairs

Plexus® structural adhesives are high-strength materials applied in a range of bond thicknesses from as little as fractions of a millimeter to inches. They are also high in modulus, adding structural stiffness to assemblies and are quite tough. These are all advantages of Plexus products: help make bonded parts lighter, stronger, and more durable. Conversely, because they are tough & strong, it would seem to make bonded structures difficult to repair.

Good News

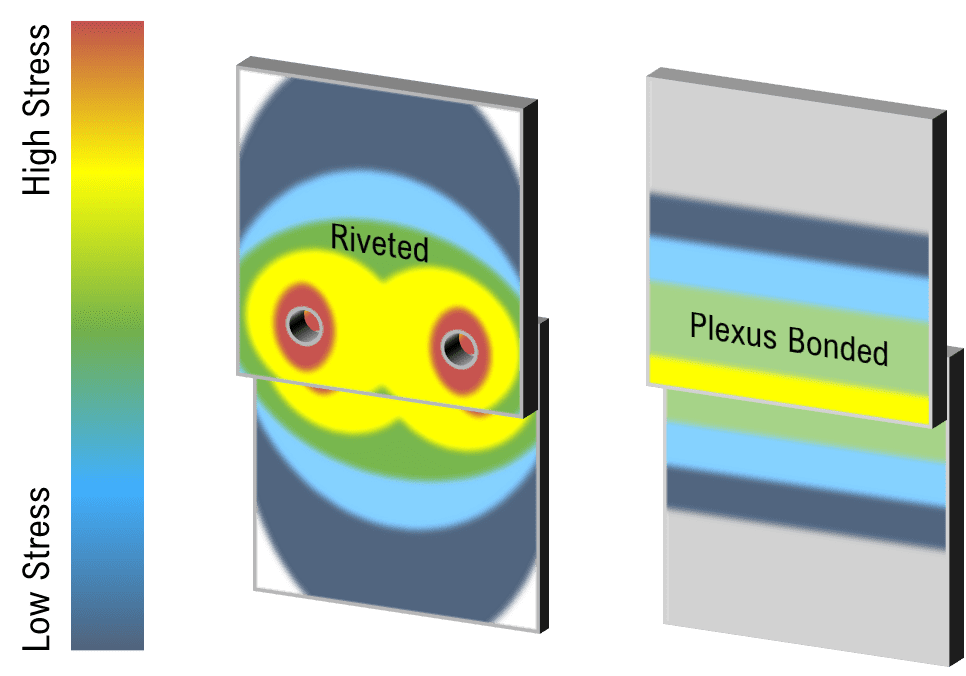

Structural adhesives absorb and distribute stress throughout a structure, balancing the forces that are placed on connection points & materials, and minimizing critical points. Mechanical fastening concentrates forces into small points of high-stress, while requiring holes in construction materials that are natural weak points. Welding is strong, but changes the nature of the underlying material and only works on metal! OK, so what?

The good news is that because of all of this load-balancing within a structure, they simply don’t “break” as much. Without the stress points created by mechanical fasteners, or the changes caused by welding, materials and assemblies absorb impacts & loads without failure from fatigue or critical stress. Because bonded structures simply do not fail as often or in the same way, the need for repair is much less frequent, and different tactics that are less costly or simpler can be employed.

Repair Tactics

In the rare case where a bonded system needs repair, several options are available. It may be possible, and most desirable, to simply clean-up the two now de-bonded surfaces and inject fresh industrial adhesive into the gap, which should be stabilized until the fixture time has elapsed (taking care to protect visible surfaces and remove squeeze-out before it cures). In more extreme cases, it might be necessary to cut the adhesive bond with a knife or saw, a procedure that can be made easier by moderately heating the structural adhesive to soften it. (Be aware of the limits of other parts of the assembly and personal safety)!! Once the adhesive is cut, then the parts can be cleaned-up and re-bonded or replaced as necessary.

Due to the relatively rarity of repairs to adhesively-bonded structures, it could be more cost-effective for a manufacturer to simply provide replacement components and recycle the damaged parts. This is commonly done in the window industry.

Your Plexus representative and our technical teams should always be consulted before repair procedures are created.

Do you have questions about stress, fatigue, repair techniques, or bonding in general? Contact Technical Support for more information.

By: Kry Wesselink, Product Manager EMEA and Sarah Vigue, Marketing Manager

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more information like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.