METAL TO METAL BONDING WITH PLEXUS® ADHESIVES

Joining metal to metal is a common phenomenon. Design engineers have been joining metal to metal for years. There are several factors engineers consider when joining metals:

- How much force will the joint see?

- How long is the joint expected to last?

- Will the joint be permanent?

- How long will it take to assemble?

- How much will it cost?

- What type of labor will it require?

When it comes to permanent joints, engineers have traditionally relied on two choices: rivets or welding. But today, there is a third proven choice that offers several advantages over traditional fastening methods: Adhesives

WHY CHOOSE PLEXUS METAL-TO-METAL ADHESIVES?

Sometimes referred to as “metal to metal glue”, adhesives are a way to chemically join two surfaces. Like rivets or welding, Plexus metal to metal adhesives provide a permanent way to bond metal to metal. In fact, there are many occasions when a Plexus adhesive will prove to be a stronger joint than rivets or welding.

However, strength isn’t the only consideration. Engineers must still factor: how long the joint lasts, how long joint takes to assemble, and how much the joint costs when completing their design. Plexus adhesives, sometimes referred to as metal to metal glue, have advantages across many of these factors:

- Continuous Connection -> Adhesives uniformly distribute stress, improving not only the joint strength, but overall durability. Rivets concentrate the stress, weakening the joint and reducing the overall durability.

- Fast Assembly -> Dispensing an adhesive is fast; often they are significantly faster than traditional joining methods. Rivets typically require pre-drilling and placement of the rivets. Welding, especially aluminum welding, requires thorough surface cleaning before starting work. With Plexus adhesives, there is little to no surface prep needed.

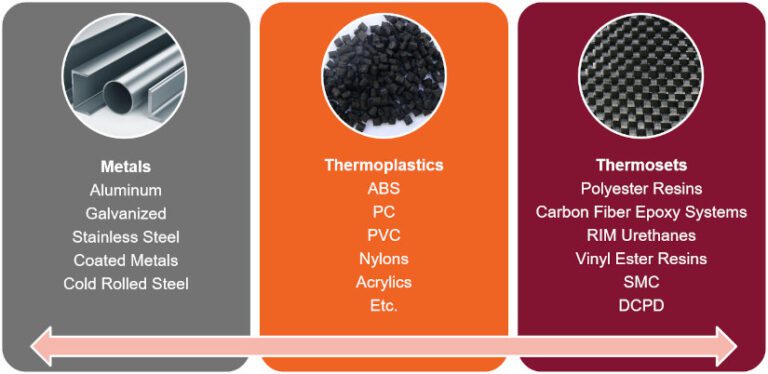

- Dissimilar Material Joining -> Plexus adhesives can join metal to a wide variety of materials. Unlike welding, Plexus adhesives can join stainless steel to aluminum, or G90 to cold rolled steel without galvanic corrosion. Plexus adhesives are significantly stronger than rivets when joining metal to thermosets, thermoplastics, and fiber reinforced plastics.

- Stiffer Structures -> continuous bond area and great surface area of connection means a stiffer structure. Alternatively, the metal can be downgauged and stiffness maintained.

- Improved Surface Appearance -> With Plexus adhesives there are no visual fasteners or surface distortions. Just a clean, smooth surface.

- Corrosion Protection -> Plexus adhesives join and form a water tight seal in one step. There are no leak paths. Additionally, the adhesive provides a barrier to electron transfer of two different materials, preventing galvanic corrosion.

- Reduced weight -> Metal to metal joints formed with Plexus adhesive are often lighter than joints formed with rivets or welding.

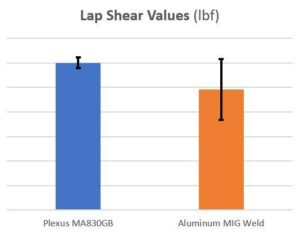

STRENGTH OF PLEXUS ADHESIVES vs. WELDING

Plexus adhesives have successfully replaced welding in a variety of structural applications. Continuous weld lines often lead to significant heat distortion and heat effected zones on the sheet metal. These distortions can weaken the overall strength and durability of the joint. As a result, the strength of a weld can vary significantly compared to bonding metal to metal with an adhesive. Consider the large standard deviation in lap shear strength of a welded aluminum joint compared to that of the same joint made with Plexus adhesive.

Comparison of adhesive strength vs welding

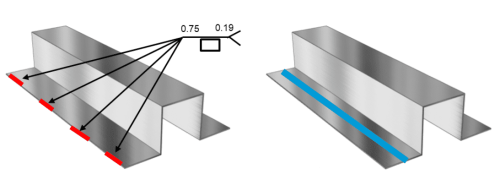

The right design is important when switching to Plexus adhesives to glue metal to metal. Butt, Corner and Tee Joints may be suitable for welding, but the design will likely need to be modified to accommodate adhesive bonding. Fortunately, the changes are usually minor, and we have an expert staff of engineers Technical Service Department that would be happy to help you select the right design.

Contact our Technical Service Department today for help replacing inconsistent welds with Plexus adhesive!

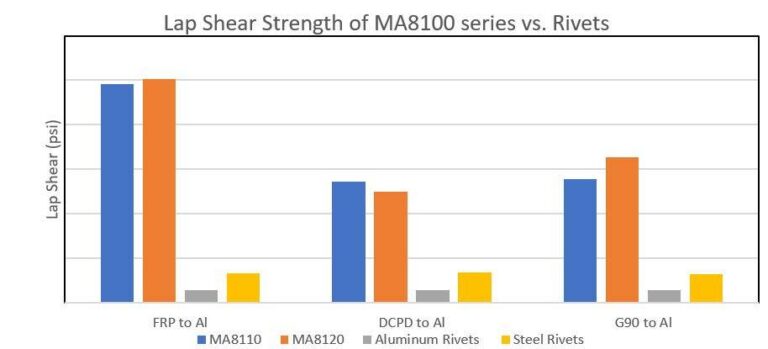

STRENGTH OF PLEXUS ADHESIVES vs. RIVETS

Plexus adhesives have successfully replaced rivets in a variety of structural applications. The strength of a joint with rivets depends on the size of the rivet, the spacing of the rivet, and the gauge of the metal. The biggest challenge related to strength and durability with rivets is stress concentration. Drilling a hole through the material to place the rivet concentrates any loads experienced by the joint on that rivet.

Contrast that with Plexus metal to metal adhesive. The adhesive provides a continuous connection, so the load can be evenly distributed across the joint. As such, Plexus adhesive achieves a much higher lap shear strength.

To prove this point, consider the following comparison. Plexus MA8110, stainless steel 1/8” rivets with 1 sq. in spacing, and aluminum 1/8” rivets with 1 sq. in spacing were used to join three dissimilar substrates: FRP to Al, DCPD to Al, and G90 to Al.

This chart demonstrates that Plexus MA8110 provides significantly higher lap shear strength than either stainless steel or aluminum rivets. Like welding, the right design is important when switching to Plexus adhesives to bond metal to metal. Contact our Technical Service Department today for help replacing weak rivets with Plexus adhesive!

SAVE TIME AND MONEY WHEN YOU SWITCH FROM WELDS TO PLEXUS ADHESIVES

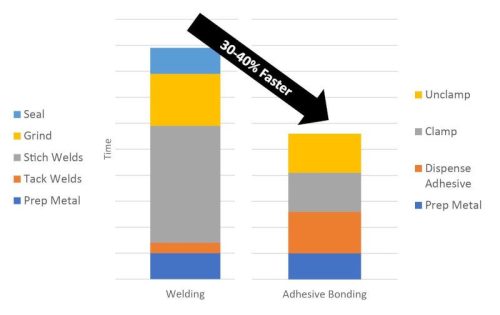

To see how using Plexus adhesives to bond metal to metal can save time and money, consider the following example.

The welding process requires 5 steps: Prep metal, tack weld, stich weld, grind, and seal. With Plexus adhesive, the process is reduced to 4 steps: prep metal, dispense adhesive, clamp, unclamp. No grinding or sealing is needed because Plexus adhesive generates significantly less heat than welding. As result, the adhesive doesn’t distort, burn through, or print through the metal, eliminating the need to re-work the part. This also allows the engineer to use a thinner gauge metal than they could if they were to weld, helping to reduce weight and cost.

Eliminating the re-work step is not the only way Plexus saves time though. Consider a time trial comparing the welding steps vs the Plexus metal to metal bonding:

As the chart illustrates, using Plexus adhesives to bond metal to metal instead of welding can reduce production time by up to 30% – 40%. The use of quality jigs and a streamlined work flow (e.g. having the assembler work on additional parts while adhesive is curing) will further increase productivity and drive down the cost / part.

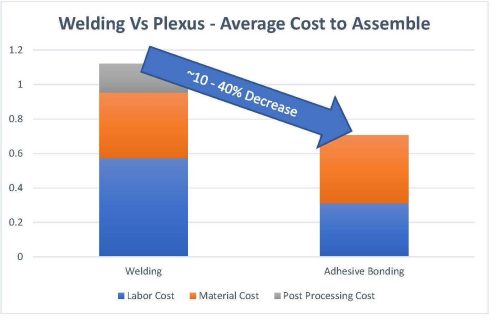

Welding requires skilled labor that is often in short supply driving up wages. Consider the total cost of assembly when you factor in labor and material costs:

As the chart shows, when you consider labor and material costs, Plexus adhesives can reduce the cost to assembly by 10% to 40% compared to welding. This doesn’t even factor in defects and rework that can arise due to the variation in welder skill.

Contact our Technical Services Department today to see if you can save time and money today by replacing your weld lines with Plexus metal to metal glue.

SAVE TIME AND MONEY WHEN YOU SWITCH FROM RIVETS TO PLEXUS ADHESIVES

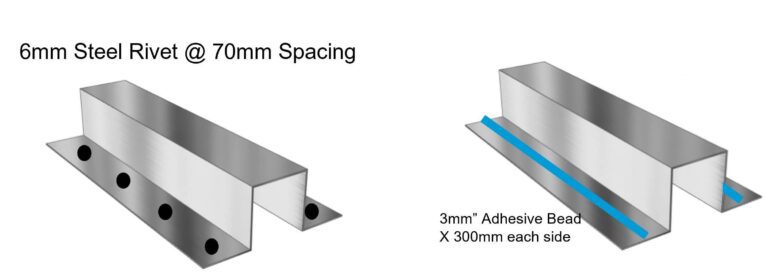

To see how using Plexus adhesives to bond metal to metal can save time and money, consider the following example.

Each process requires four steps. In the case of rivets, the process is:

1) place substrate

2) drill hole

3) place rivet

4) pop rivet

For a Plexus metal to metal adhesive, the process is:

1) dispense adhesive

2) mate substrate

3) clamp

4) unclamp

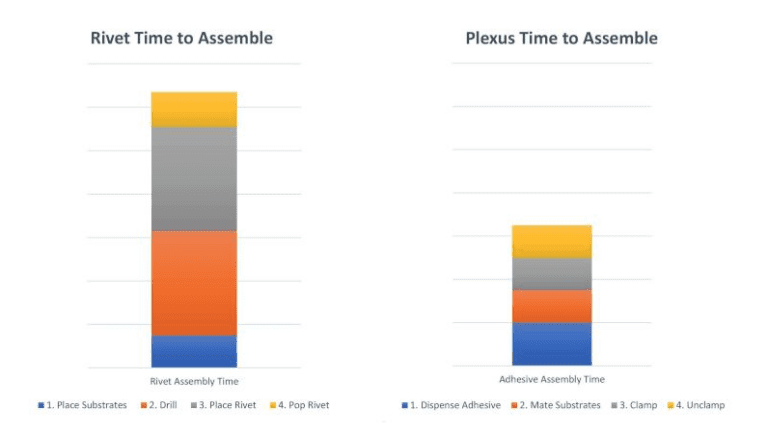

However, time trials show that the using a Plexus Adhesive to bond metal to metal is faster than using rivets.

As the graph shows, using Plexus adhesives to bond metal to metal instead of welding can reduce production by up to 50%. This graph doesn’t include the effects of worker fatigue caused by the hard, repetitive riveting motion.

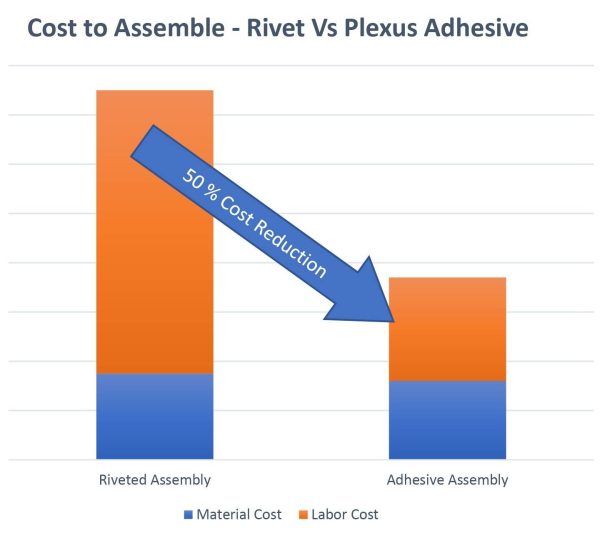

This time savings has a direct effect on the total assembled cost of the part.

As the graph clearly shows, replacing rivets with Plexus adhesive has the potential to reduce the total assembled cost by up to 50%.

Contact our Technical Services Department today to see if you can save time and money today by replacing your rivets with Plexus metal to metal adhesive.

SEE HOW EASY IT IS TO APPLY PLEXUS ADHESIVES

Seeing is believing. Watch this short video to see how easy it is to apply Plexus adhesives.

MAKING THE SWITCH TO PLEXUS ADHESIVES

Before starting metal to metal bonding or using a metal bonding adhesive in general, there are a few important considerations:

I. What metal or other material will be bonded?

II. What surface preparation is required to get a good adhesive bond to metal?

III. How to bond metal with Plexus adhesives?

I. What metal or material will be bonded?

Plexus® Structural adhesives bond a variety of different metals including coated metals:

- Aluminum – Mill Finished

- Mild Steel

- Galvanneal

- Aluminum – Coil Coated

- Hot Dipped Galvanized (HDG)

- Chromate

- Aluminum – Anodized

- Electrogalvanized (EZG)

- Stainless Steel

- Aluminum – Extrusions

- Galvalume

- Magnesium

- E-Coated Metals

- Powder Coated Metals

- Nickel

Have a question about a specific grade of metal or coated metal to be glued? Take a look at our Adhesive Selector Guide or contact our technical service department via the contact on the right to have a test done.

II. Surface preparation

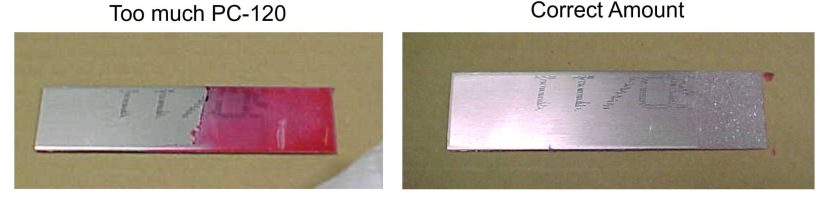

Several Plexus adhesives including the MA200, MA800, and MA8000 Series can bond metal to metal without a primer. The Plexus MA8000 series can even be used galvanized or zinc coated metal without primer. However, some of the other adhesives in the Plexus portfolio require a Cleaner Conditioner called PC120. PC120 helps to clean the metal surface and improve strength of the bond over time. PC120 is dyed pink so that you can easily see where the metal has been properly cleaned.

Below is the typical surface preparation required to glue metal to metal:

| Surface | Typical Surface Preparation | Typical Surface Preparation |

| Type of Metal | Plexus® Primerless Adhesive | Plexus® Adhesive |

| Lightly Oxidized Metals | Dry Rag Wipe or Solvent Wipe | PC120 Cleaner Conditioner |

| Heavily Oxidized Metals | 1. Solvent Wipe (IPA or Acetone) 2. Sand or Grind 3. Solvent Wipe | 1. Solvent Wipe (IPA or Acetone) 2. Sand or Grind 3. Solvent Wipe |

| Coated Metals* | Dry Rag Wipe or Solvent Wipe | Dry Rag Wipe or Solvent Wipe |

*Testing needed to confirm adhesion to different coatings

Salt spray results using PC120 and Correct Amount to Use:

III. How to bond metal with Plexus Adhesives

Plexus adhesives are 2-part (shortened to “2K”) adhesives that create a chemical reaction when mixing. The adhesives are typically mixed in a static mixer and dispensed unto on side. The two materials are mated together and then held in place until the adhesive has had time to cure or harden. This is often done by clamping. The adhesive continues to cure and once it has developed enough strength, the assembly can be unclamped.

Here are some key things to know:

- Working Time (also known as Open Time): The time elapsed between the moment Parts A and B of the adhesive system are combined and thoroughly mixed and the time when the adhesive is no longer useable.

- Fixture Time (also known as unclamp time): The time elapsed between the moment Parts A and B of the adhesive system are combined, thoroughly mixed and parts put together and the time when the assemble can be unclamped. This can change depending on the ambient temperature and temperature of the parts.

- Fixture strength: If the part needs to be lightly moved around, then 50 PSI might be enough strength. If the part will see higher loads after being put together, then 500 or 1000 PSI might be needed. Our Technical Service Department can help provide additional information. Get in touch with our technical service team via the contact form on the right.

BENEFITS OF BONDING METAL TO METAL WITH PLEXUS ADHESIVES

Strength and Durability of Plexus Adhesives on Metal to Metal Bonding

Proper usage of Plexus® Adhesives for bonding metals is expected to have significant advantages over traditional joining methods e.g. rivets, nuts, screws. Gluing a part can be a lot faster and can help speed up most assembly process. The continuous connections, strength and durability of adhesives may help to create a stronger structure than other joining methods.

Bonding Dissimilar Materials with plexus adhesives

Not only does Plexus® adhesives bond metal to metal, they are also often used to bond metal to composites and bond metal to thermoplastics.

For more information on bonding dissimilar substrates, get in touch with our technical services department via the form on the right.

ADHESIVE SELECTOR GUIDE

Looking to bond certain metal or coated metal? See our adhesive selector guide for full details.

If you have any questions about our adhesives or a project you are working on, please don’t hesitate to contact our technical service team.