Post Takeaways

This second post will help installers and users of Chockfast products to understand the effects that cold temperatures have on the physical properties of non-shrink epoxy grouts (also known as non-shrink construction grout) and chocks when exposed to cold ambient temperatures.

Outline

- Introduction

- How Cold Temperatures Effect Installation Properties

- Viscosity

- Working Time

- Initial Cure Time

- How Cold Temperatures Effects In-Service Properties

- Brittleness

- Min Service Temperature

- Contraction – Coefficient of Thermal Expansion

- Implications for the Installer

- Final Thoughts on Temperature

Cold Weather Grouting: Installing Chockfast Epoxy Grout for Critical Machinery

Part 2 of the Cold Weather Installation Series

When installing critical industrial machinery, precision and durability are paramount. In cold climates, however, even the most reliable materials – like Chockfast epoxy grout – can behave differently. Cold weather grouting presents unique challenges that, if not addressed, can compromise the integrity of your installation and long-term machinery performance.

In this second installment of our three-part series on industrial machinery maintenance in cold weather, we’ll explore how low temperatures affect the installation and performance of Chockfast epoxy grouts or Chockfast epoxy chocks including Chockfast Orange. Whether you’re an installer, engineer, or equipment designer, understanding these cold-weather dynamics is essential to applying grouting best practices and ensuring successful outcomes.

How Cold Temperatures Affect Installation Properties

Cold weather can significantly alter the behavior of epoxy-based grouting solutions during installation. Here’s what you need to watch for:

Viscosity

As temperatures drop, epoxy chocks and grouts become thicker and harder to mix and pour. Increased viscosity can lead to poor flow, air entrapment, and incomplete cavity filling. To maintain optimal performance:

- Refer to the Recommended Application Temperatures in the Technical Data Sheet.

- Store materials in a warm environment before use.

- Use heated enclosures or warming blankets on-site.

- Mix thoroughly and monitor flow characteristics.

Working Time

Cold conditions extend the working time of heavy machinery adhesives, increasing the window for proper placement. This may lead to surprises on-site. To mitigate:

- Monitor ambient and material temperatures.

- Adjust your workflow and team coordination.

- Use temperature-controlled environments when possible.

Initial Cure Time

Low temperatures slow the chemical reaction that cures epoxy grout. This means longer waiting times before the chock can be loaded or forms can be removed. Premature loading can compromise alignment and structural integrity. Best practices include:

- Using heat blankets or tenting to maintain curing temperatures.

- Scheduling installations around expected weather conditions.

- Consulting manufacturer guidelines for cure time adjustments.

How Cold Temperatures Affect In-Service Properties

Once installed, epoxy grout for cold climates must perform reliably under harsh conditions. Here’s how cold weather impacts long-term performance:

Brittleness

Epoxy compounds become more brittle in low temperatures, reducing their ability to absorb shock and vibration. This is especially critical in dynamic machinery environments. To negative effects from brittleness, be sure to:

- Verify performance data from the manufacturer.

- Limit impacts to the foundation structure as much as possible, especially at very cold temperatures.

Contraction – Coefficient of Thermal Expansion

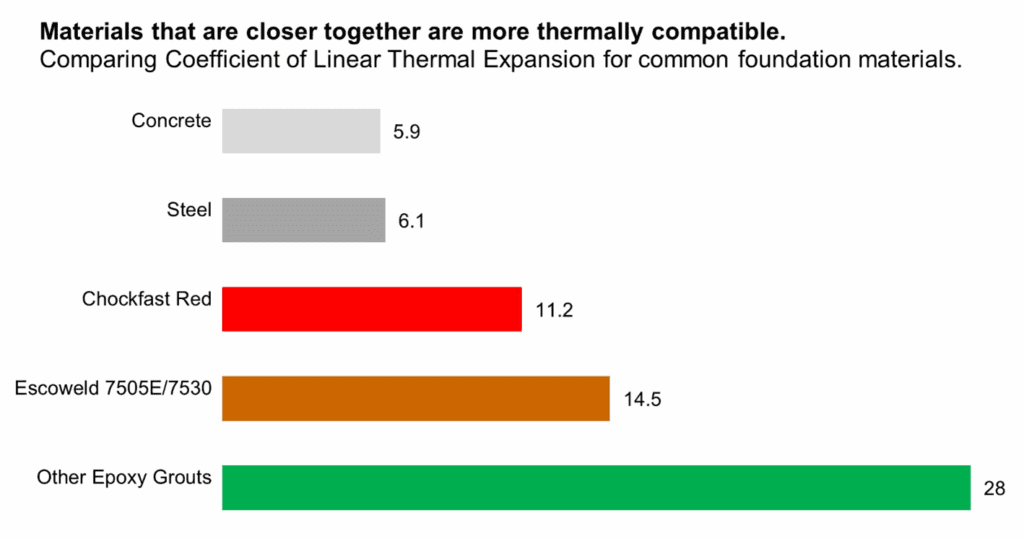

Temperature fluctuations cause materials to expand and contract. This is compared using the Coefficient of Linear Thermal Expansion (CTE), which is a measurement of the amount a material will expand or contract when it is heated up or cooled down. The following is a listing of the CTE’s for common materials in a dynamic foundation system of a as published by their respective manufacturers:

The closer the CTE of two materials are, the more compatible those materials are. They are compatible because they will tend to grow and shrink together as the outside temperature increases and decreases. If not accounted for, this can lead to misalignment or stress on machinery.

Design considerations include:

- Planning for thermal movement in expansion joint design. For foundations expecting exposure to large thermal cycles, place expansion joints closer together.

- Ensure anchor bolts do not bond directly to epoxy chock or grout.

Implications for the Installer

Cold-weather installations require more than technical skill—they demand proactive planning and environmental control. Key takeaways for installers:

- Material Handling: Store Chockfast components in temperature-controlled environments.

- Site Preparation: Use heated tents or enclosures to maintain ambient conditions. We will discuss this more in the next part of the Cold Weather series.

- Temperature Monitoring: Track surface and air temperatures with infrared thermometers or data loggers.

- Timing Adjustments: Allow for longer mixing, pouring, and curing times.

- Documentation: Record environmental conditions and curing times for QA/QC.

Collaboration between installers, engineers, and designers is essential to ensure that industrial repair solutions perform as intended in cold climates.

Final Thoughts on Temperature and Grouting Best Practices

Temperature is a critical variable in the success of cold weather grouting. From installation to long-term performance, understanding how cold affects Chockfast epoxy grout helps professionals make informed decisions and avoid costly mistakes.

By planning ahead, controlling your environment, and applying grouting best practices, you can ensure that even in the harshest conditions, your machinery installations remain solid, aligned, and reliable.

Stay tuned for Part 3 of our series, where we’ll discuss more recommendations to achieve a successful installation of Chockfast epoxy grouts and chocks in colder ambient temperatures.

To further discuss planning for and performing field verification of Chockfast precision epoxy grouts or chocks or any of our machinery maintenance adhesives, please contact ITW Performance Polymers Technical Services or your local Chockfast Worldwide Distributor Network representative.

By: Christopher Matthews-Ewald, Senior Applications Engineer

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Cheat Sheet: Chockfast® Epoxy Grout Typical Installation Steps and Laying The Foundation For Success With Chockfast® Epoxy Grouting.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.