Nylon Bonding Introduction

Nylon (also known as Polyamide) can be a tricky material to bond with a structural adhesive. Some manufacturers resort to expensive plasma, flame or primer steps in order to get a good bond to nylon. Select Plexus® structural adhesives can help eliminate or minimize these timely or costly extra preparation steps.

Problem:

An Original Equipment Manufacturer (OEM) was looking for an optimal solution to bond nylon to various materials including ABS and E-Coated Steel. The customer’s project requirements were:

- To cross bond nylon to other substrates (dissimilar material bonding)

- To bond nylon without extensive surface preparation

- To maintain a structural bond at intermittent temperatures up to180°F (82°C)

Solution:

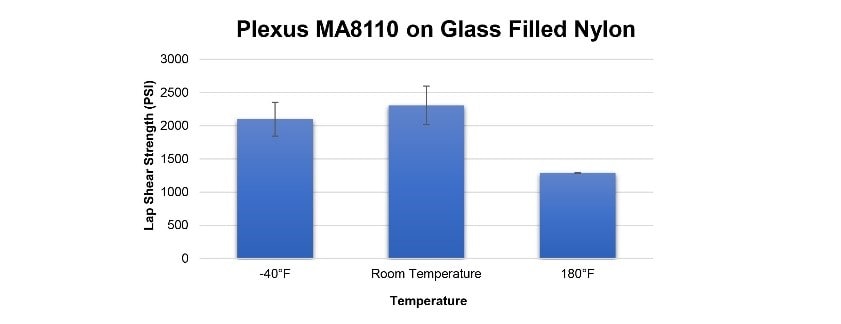

The customer tested Plexus MA8110 adhesive. Below results show Plexus MA8110 provided the high strength required to bond the glass filled nylon. The adhesive had excellent strength at high temperature of 180°F (82°C). No surface preparation was necessary.

This chart demonstrates that Plexus MA8110 provides significant high lap shear strength to bond glass filled nylon at a wide range of temperatures. If you’re looking for more details on Plexus MA8110, please contact our Technical Service Department.

How Acetone Wipes Increase Lap Shear Strength

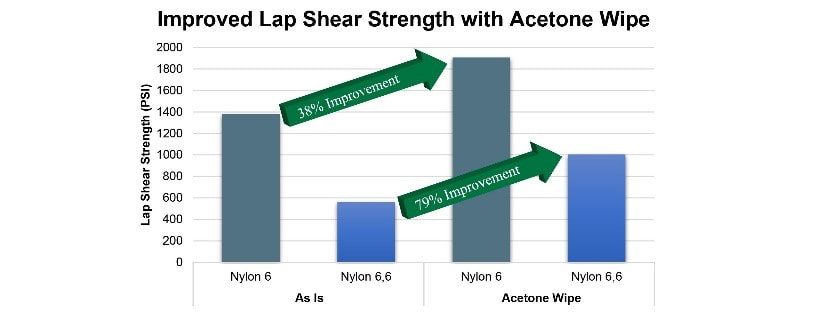

It is important to note that on some grades of nylons and/or if mold release is used, a solvent wipe helps improve adhesion. Additional testing on other grades of nylon shows an increase in lap shear strength when wiped with acetone.

There are many different grades of nylon and as shown here, optimal results were created with Plexus MA8110 and Plexus MA8120. Also observed in this study is that Nylon 6 is easier to bond than Nylon 6,6. As a result, it is recommended that to ensure the ultimate bonding success, one should always thoroughly test and screen the particular grade of nylon being considered to bond, prior to final application.

Contact our Technical Services Department for more information on which Plexus adhesive is most suited for your application.

By: Max VanRaaphorst, Business Development Manager and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.