All Plexus® brand product datasheets contain particular terms that may or may not be familiar to you, depending on how involved you are in buying, specifying, or using structural adhesives. We’re going to highlight a few of these for your edification. The adhesive related terms are: thixotropy, viscosity, and (under the heading of rheology – the study of flow) shear-thinning.

Viscosity

Viscosity is probably the most familiar of the three terms. Viscosity refers to how ‘thick’ a liquid is or how quickly it flows. Viscosity is influenced by the chemical nature of the fluid and very importantly by temperature. Lubricants like motor oil usually state their warm and cold temperature viscosity right in their names e.g. 10W30. Higher viscosity fluids flow slowly and require more force to pump.

Thixotropy

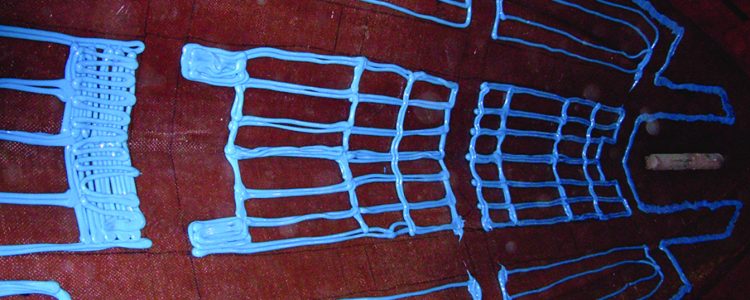

Thixotropy is the tendency of a fluid to stay where it is. Thixotropy is created by adding specific agents to materials to help them resist flow, sag, and dripping. This property is what allows adhesives to be applied vertically, or even upside-down without moving or falling off the surface. The thixotropy of Plexus structural adhesives is what is responsible for their superior gap-filling properties in large bond lines. Thixotropy is also affected by temperature, but in a way that for some types of adhesive may be opposite to viscosity.

We often explain the difference between the two with the example of maple syrup and mayonnaise – two familiar fluids. Maple syrup has a fairly high viscosity. It flows slowly, tends to keep flowing, and will drip or fall off of any vertical surface. Mayonnaise, by contrast, has low viscosity – it flows quickly and easily when you squeeze the bottle, but once force is no longer being applied, it stays where it is. That illustrates the two properties.

Shear-Thinning

Finally, there is a fluid property called “shear-thinning.” Fluids with this property lose their thixotropy when a force is applied to the fluid. Essentially, this is what gets the mayonnaise out of the bottle. Shear-thinning allows us to use much smaller pumps & applicators to extrude adhesives that have relatively high-viscosity & thixotropy. Once the material is extruded and the force is dissipated, the thixotropy of the fluid recovers and it becomes non-sag once more.

In cold temperatures, viscosity rises, and slows extrusion. However, since all chemical processes slow at low-temperature, thixotropic recovery also slows. That’s why in winter, a high-viscosity adhesive may sag more than in summer, when the viscosity is much lower! In spring and fall, when the shop floor temperatures tend to be cooler than summer, or when the shop is closed and heated in winter, you may notice this phenomenon.

Do you have questions about flow, pumping, thixotropic adhesives, or adhesive bonding in general? Contact Technical Support for more information. If you’re interested in other terminology and definitions, visit our polymers glossary.

By: Kry Wesselink, Product Manager EMEA and Sarah Vigue, Marketing Manager

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: What is fixture time anyway? and Is it strong enough?.

For more information like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.