Post Takeaway

To calculate the density, Specific Gravity (SG) is a unitless measurement that can be used to determine density with any of the Chockfast solutions.

Outline

- Introduction

- Using SG to Determine Density

- Using tools to Determine Volume

- Using Density and Volume to Determine Weight

How can I determine the weight of the Chockfast in my installation?

Whether used for evaluating the effectual mass and stiffness in a foundation system design for compressors, or just the overall weight of an epoxy grout installation, the answer can be complex. The mass of non-shrink epoxy chocks and non-shrink grouts is used in different analyses and calculations for heavy equipment adhesive installations. However, a quick search will not provide a clear answer on how much a given volume of Chockfast industrial epoxy product will weigh. This article will help you to better understand.

Engineers also use the weight of the Chockfast epoxy to accurately characterize the dynamic loads of the foundation system, design effective vibration mitigation strategies, ensure stability and safety of the foundation system, and optimizing equipment performance. This is especially important for ensuring the proper geometry and mass of the foundation system for mitigating vibrations as this affects the system’s natural frequency and how it responds to dynamic forces.

To provide more clarity, we start with our Chockfast technical literature or the technical data sheets that publishes Specific Gravity for each of our epoxy chocking or epoxy grouting solutions. Specific Gravity, abbreviated as SG, is a number commonly used in many industries and with many industrial adhesives that compares the density of a material (in this case Chockfast) to the density of a reference material, which for solids is usually pure water at a temperature of 39.2°F (4°C).

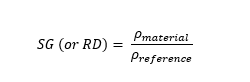

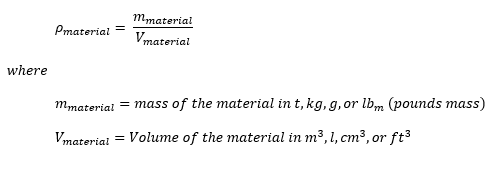

The following formula is universally accepted for calculating the Specific Gravity (SG), or relative density (RD), using the density of a material (Pmaterial) compared to the density of a reference material (Preference).

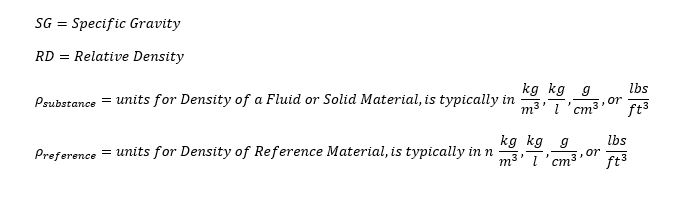

Where:

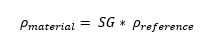

If one needs to specifically find the density of a product, we can simply rearrange the formula as below:

How can I get the density of Chockfast products?

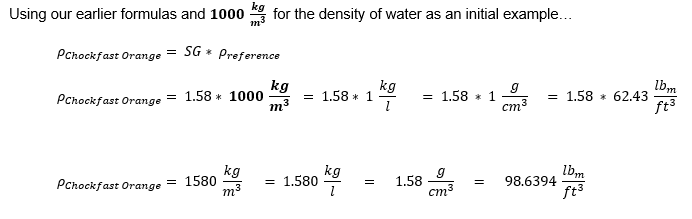

If we use Chockfast Orange as an example, we can find in Technical Data Sheet #659, that the specific gravity is 1.58.

Looking up the density of water, we find that it is commonly accepted to be

- Source – Oberg, Erik, Franklin D. Jones, Holbrook L. Horton, and Henry H. Ryffel. Machinery’s Handbook: A Reference Book for the Mechanical Engineer, Designer, Manufacturing Engineer, Draftsman, Toolmaker, and Machinist. New York: Industrial Press, 2012. Print.

- Specifically – Table 15 in Properties, Treatments, and Testing of Materials section, page 380 in 29th

How can I determine the weight of my epoxy grout installation of Chockfast?

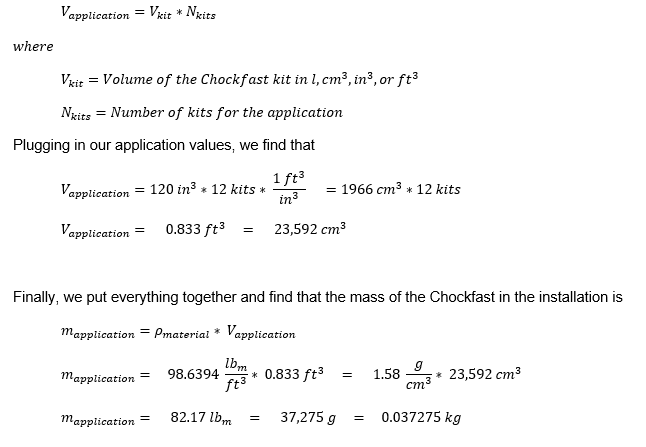

Now that we have determined the density of the Chockfast, we are nearly there! All we need to do is use the volume of the pour, including all overpours, either from the design or the actual installation, into the density formula.

The commonly accepted formula for density is

We can easily rearrange the formula to use our known values of density and volume to calculate the mass of an installation.

The Chockfast Grout Calculator is used in the installation best practices process to allow users to easily determine the volume of an installation. Please visit the calculator.

If we assume that an application, including overpours, calls for 12 small units of Chockfast Orange with each unit containing a volume of 120 in3 (1966 cm3), we can calculate a total volume of:

By: Christopher Matthews-Ewald, Senior Applications Engineer and Erik Barkmeyer, Applications Engineer

To further discuss your Chockfast weight calculation of precision epoxy grouts, or chocks or any of our machinery maintenance adhesives, please contact ITW Performance Polymers Technical Services or your local Chockfast Worldwide Distributor Network representative.

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Cheat Sheet: Chockfast® Epoxy Grout Typical Installation Steps and Critical Machinery Installation In Cold Weather? Find Out How To Plan For Success.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.