Introduction to TPO Bonding & Other Low Surface Energy Plastics

Plexus is a global leader in bonding plastics, particularly amorphous plastics like ABS, polycarbonates, PVC and acrylic plastics. However, there has been a long-standing issue when bonding low surface energy semi-crystalline plastics.

- Amorphous plastics– like PPO, Polycarbonate, Polystyrene, Kydex, PVC, Acrylic, and ABS

- Semi-crystalline plastics – like PET, Nylon, PBT, Acetal, Polypropylene (PP), High Density Polyethylene (HDPE), high density Polypropylene (HDPP), or Thermoplastic PolyOlefins (TPOs)

Amorphous plastics can be easily bonded with traditional Plexus MMA adhesives (methyl methacrylate adhesives). Semi-crystalline plastics are much more difficult to bond as they tend to be very inert materials (no chemical sites with which to react) or they have very low surface energy (difficult to wet out and mechanically grab the surface of the plastic).

However, with the advancements in adhesive technology, specifically Plexus adhesives, there has been a breakthrough in achieving reliable bonding for these challenging semi-crystalline materials. In this blog post, we will explore the effectiveness of Plexus adhesives for bonding low surface energy substrates.

Understanding the Challenges of Bonding Low Surface Energy Substrates

Low surface energy plastics, which include materials like TPO, PET, PBT pose unique challenges for adhesive bonding. Traditional adhesives often struggle to form strong and durable bonds with these substrates due to their low surface energy, which hinders the adhesion process. Manufacturers have historically relied on mechanical fastening or adhesive primers and glues that contain or utilize hazardous chemicals. These methods can be very expensive, time-consuming/inefficient, less reliable, and harmful to both the environment and operators.

Plexus Adhesives: A Game-Changer for Low Surface Energy Bonding

The Plexus team at ITW Performance Polymers has introduced two new adhesives, as promising solutions to overcome the difficulties of bonding low energy surface plastics:

- Plexus PU2105 – Structural polyurethane adhesive

- Plexus H4110 – Semi-structural, hybrid adhesive

When bonding low surface energy substrates, in conjunction of a surface pre-treatment, these two Plexus adhesives exhibit excellent adhesion properties, allowing them to form strong bonds with various materials specifically plastics like TPOs. Furthermore, Plexus adhesives provide exceptional resistance to environmental factors such as moisture, temperature variations, and UV exposure. This ensures the longevity and durability of joints bonded with Plexus acrylic adhesives.

The Role of Plasma Surface Pre-Treatment

Plasma treatment involves exposing the substrate’s surface to ionised gas, creating a highly chemically active surface. This process helps to increase the surface energy and improve the adhesion of these new Plexus adhesives. Plasma treatment can be particularly beneficial for precision manufacturing and materials with very low surface energy, such as certain types of plastics like TPOs.

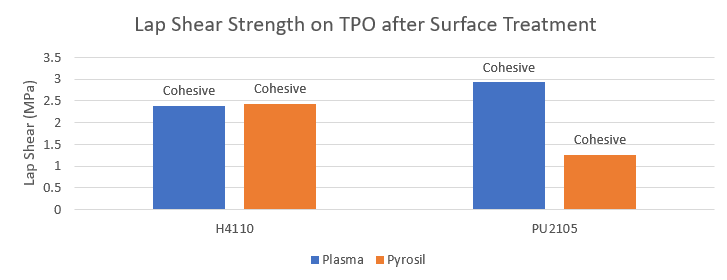

By using plasma pre-treatment in combination with Plexus adhesives, manufacturers can achieve even stronger and more reliable bonds on challenging low surface energy substrates. The pre-treatment process ensures that the adhesive can form intimate contact with the substrate, enhancing adhesion and overall performance. Other pre-treatments, flame treatments and deposition of amorphous silicon dioxide, have also been tested and show promising results. Examples of their quality performance are demonstrated below, providing cohesive failure on a TPO.

Conclusion

Plexus adhesives have revolutionized the ways it is possible to bond low surface energy substrates, providing reliable, efficient, and durable solutions for industries across the board. With their exceptional ability to bond materials like TPOs when used in conjunction of a surface preparation.

If you have questions on using Plexus structural adhesives, contact our Technical Services team today. Whether you are looking for a TPO adhesives, EPDM glue, or PVC adhesive, our technical specialists have the answers you need.

By: Elisabeth Baumann, Technical Service Lab Supervisor

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.