As electric vehicles (EVs) continue to redefine the future of e-mobility, the materials and technologies used in their construction are evolving rapidly. Among these innovations, Plexus Methyl Methacrylate (MMA) structural adhesives are playing a pivotal role in enhancing the performance, reliability, and manufacturability of EV battery systems. From bonding battery cells to sealing pack housings, Plexus MMA adhesives offer a unique combination of strength, speed, and versatility that makes them ideal for demanding EV applications.

Bonding Modules & Cells

In EV battery modules, structural integrity and thermal management are critical. MMA adhesives from Plexus provide high-strength and exceptionally durable bonds between module plates and cells, featuring excellent adhesion to PET foils. This ensures that the assembly remains secure under vibration, thermal cycling, and mechanical stress—key concerns for electric vehicle battery manufacturers.

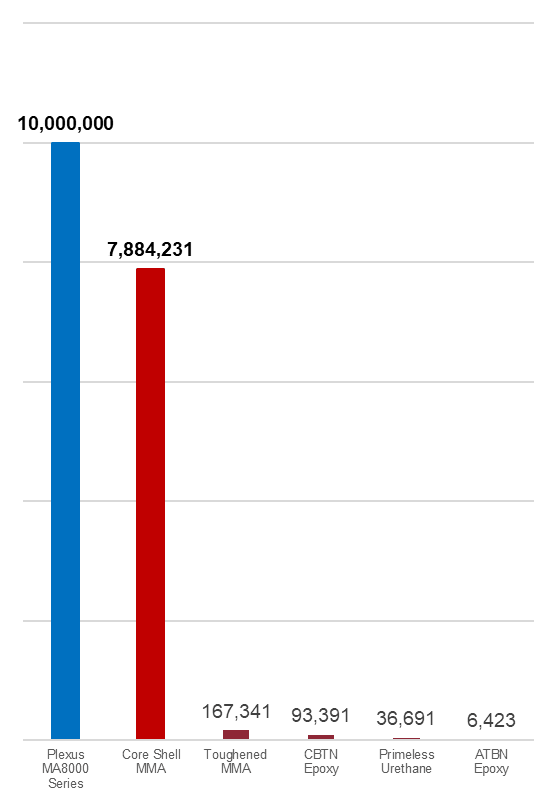

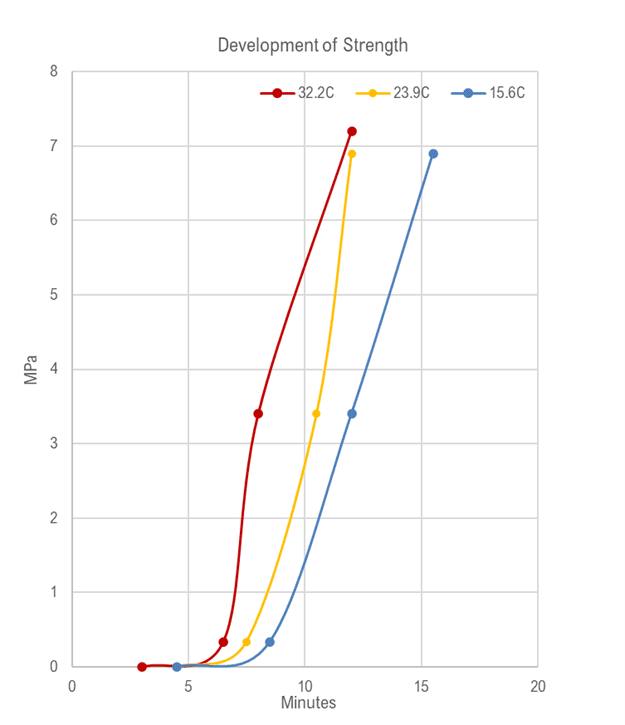

MMA adhesives distribute loads evenly across the bonded surface, improving durability and allowing for lighter and more durable designs— an essential advantage for battery manufacturers for electric cars. Thanks to their rapid cure times, Plexus MMA adhesives outperform many other industry adhesive technologies, developing strength up to 3X faster than conventional industrial glue or silicone manufacturers’ sealants due to their free-radical reaction mechanism that accelerates strength development for a fast, secure bond.

Bonding Cylindrical Cells into Pack Structures

Cylindrical cells are widely used in EV battery packs due to their energy density and modularity. However, securely integrating them into pack structures requires adhesives that are fast-curing, durable and can handle thermal cycling, vibration, and other stresses. Plexus MMAs offer a variety of options for electric cars battery companies bonding cylindrical cells, including tray and ribbon options, with products that offer ultra-fast and ‘cure on demand’ options for ribbon applications or other configurations.

Bonding Brackets, Mounts, Inserts, and Clips

Battery pack housings incorporate a variety of components—brackets, mounts, inserts, and clips—to support and secure internal elements. These parts may be made from metal, composite, or plastic, and bonding them reliably to the housing is a challenge for many EV battery manufacturers.

Plexus MMA adhesives excel in bonding dissimilar substrates, including metals, composites, and engineered plastics. Additionally, MMA adhesives cure quickly at room temperature, enabling fast production cycles without the need for heat or complex curing strategies. This ease of application makes them ideal for both automated and manual assembly lines. This is especially beneficial for electric vehicle battery manufacturers seeking scalable solutions.

Plexus MMA adhesives provide a tough, flexible bond that accommodates differential movement between cells and pack materials. Their ability to bond metals and plastics without primers simplifies the process and reduces preparation time.

Moreover, MMA adhesives offer gap-filling capabilities, allowing for consistent bonding even when surface tolerances vary—an important feature when working with large volumes of cells.

Water and Airtight Sealing of Pack Housings

Battery packs must be protected from moisture, dust, and other environmental contaminants. Plexus MMA adhesives are formulated to deliver durable water and airtight sealing, ensuring long-term protection of sensitive electronics and cells.

Unlike traditional sealants, MMA adhesives combine sealing and structural bonding in a single step. This dual functionality reduces part count and assembly time while enhancing the overall robustness of the battery enclosure.

Methacrylate adhesives’ resistance to chemicals and thermal cycling makes them particularly well-suited for harsh automotive environments, where reliability is non-negotiable.

Why Plexus MMA Adhesives Stand Out

- High Strength: Capable of withstanding mechanical loads and vibrations typical in EV applications.

- Fast Cure Speed: Rapid curing at ambient temperatures accelerates production and reduces downtime.

- Versatile Bonding: Bonds a wide range of substrates, including metals, composites, and plastics.

- Excellent Adhesion to PET Foil: Ideal for battery insulation and wrapping applications.

- Ease of Application: No need for primers or surface treatments; suitable for automated dispensing.

Conclusion

As EV battery designs become more complex and performance-driven, the choice of adhesive technology becomes increasingly strategic in the application of adhesives. Plexus MMA industrial adhesive solutions (structural adhesives) offer a compelling advantage for electric cars battery companies and EV battery manufacturers seeking strength, speed, and versatility in their bonding and sealing processes.

Whether you’re assembling modules, integrating cells in packs, or sealing housings, Plexus MMA adhesives deliver the reliability and efficiency needed to power the next generation of electric vehicles.

By: Kry Wesselink, Product Manager EMEA

Adhesive technology is an important component of EV battery pack manufacturing. ITW Performance Polymers offers a full range of globally available adhesives to meet all critical battery requirements.

If you have questions about EV manufacturing with adhesives, technical questions about Plexus® acrylic adhesives, or bonding in general, contact Technical Support for more information.

Need some help? Ask a technical question and find a solution!

Further reading: Hybrid Adhesives: Greater than the Sum of its Parts?, Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.