How to Repair, Rebuild & Protect Your Equipment with the Devcon Wear Guard™ Elevated Temp Coatings

Founded in the 1950s to develop products that substituted as alternatives to welding, Devcon has grown to offer a vast array of high performance and wear coating oriented products to meet the needs of many industries. Elevated temperatures can degrade the adhesion of wearing compounds. To prevent this, Devcon designed products specifically formulated to operate in elevated temperatures.

Key Features:

- Short Down Time: Designed to get equipment up and running quickly

- Durability: Products extend equipment life and reduce maintenance and replacement costs.

- Ease of Use: Simple application process requires minimal training.

- Variety of Systems: Abrasive wear happens in a variety of industries that involve elevated temperatures and Devcon wear and protective coatings has many variations to help protect different needs

The durable nature of Devcon wear coatings also holds up to harsh environments. The easy to apply products allow the operator to get the equipment up and running quickly with minimal training. The wear coating products we list below are designed to protect from both low temperatures and perform up to high temperatures such as 450°F / 232°C.

The Devcon Wear Coating Product Highlights

- Devcon Wear Guard 300RTC:

- The RTC stands for room temperature cure.

- Temperature Range: Up to 300°F (148°C) in wet or dry conditions.

- Curing: Room temperature cure, no post-bake required.

- Durability: Outperforms other compounds in the markets.

- Application / HiVis Color: Bright blue color for easy visibility in low-light areas.

- Devcon Wear Guard High Temp:

- Temperature Range: Up to 450°F (232°C).

- Curing: Requires a post-bake step for full potential.

- Application: Suitable for challenging environments like steel mills.

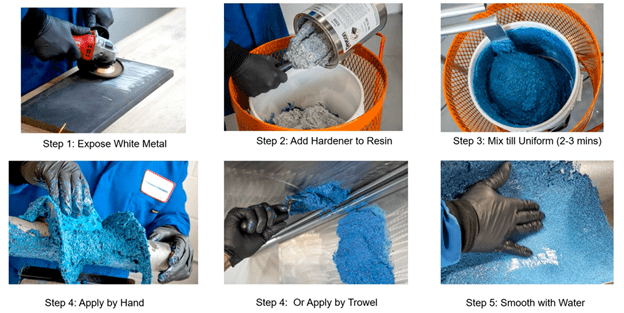

Both of these wear coatings are easy to apply. The first step is to get a good surface prep by achieving a white metal finish through grinding or abrading. Establish a uniform mix of the product and apply by hand or trowel. All wear coating products have the ability to be smoothed with either isopropyl alcohol or water, depending on the formulation.

Examples of Wear Coating in Action

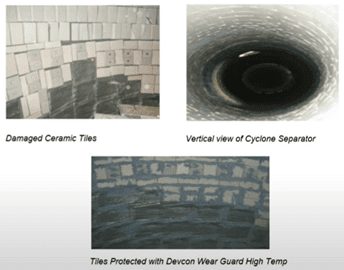

- High Temp Process Cyclone:

- Application: Devcon Wear Guard High Temp was applied to the seams of a tall vertical cyclone separator used for drying coke in steel production.

- Problem: Ceramic tiles were wearing at the seams. Devcon Wear Guard High Temp was applied on the tile seams.

- Solution: After application, the cyclone was gradually turned on to complete the post-bake process.

- Outcome: The wear coating protected the tiles, significantly extending their lifespan and avoiding costly replacements.

- Read the case study.

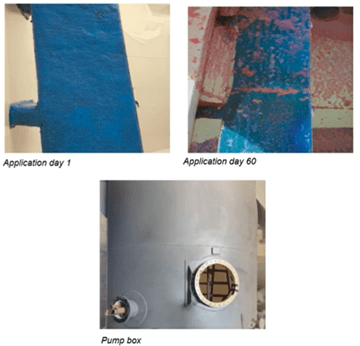

2.Pump Box in Potash Harvesting:

- Application: Devcon Wear Guard 300RTC was used in a pump box operating at 250°F (121°C) in a potash mine.

- Problem: The previous wearing compound broke down within a month.

- Solution: Devcon 300RTC was applied to the baffles and interior tank walls.

- Outcome: After 3 months, the Devcon coating showed no signs of wear, while the competitor’s product did. At 9 months, it continued to exceed performance expectations, leading to a decision to fully coat the pump box with Devcon 300RTC.

- Read the case study

The Devcon Solution

Devcon branded products enable customers to rebuild, repair, and protect equipment in harsh environments. These durable and innovative wear coatings are easy to apply and backed by dedicated technical & customer support. With over 70 years of experience, Devcon provides reliable solutions for maintenance needs through global manufacturing and supply networks.

- Devcon®101 Series: Wear Resistance with the Devcon Wear Guard™ Family

- Devcon®101 Series: Wear Resistance with Devcon DFense Blok™

- Devcon® 101 Series: Fast Curing, Wear Resistance with Devcon Coatings

By: Tony Mell, N.A. Sales Director and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Durability With Devcon® Protective Coatings: Proven In Multiple Industries and The Top Four Types Of Wear Impacting Industrial Equipment.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.