Problem

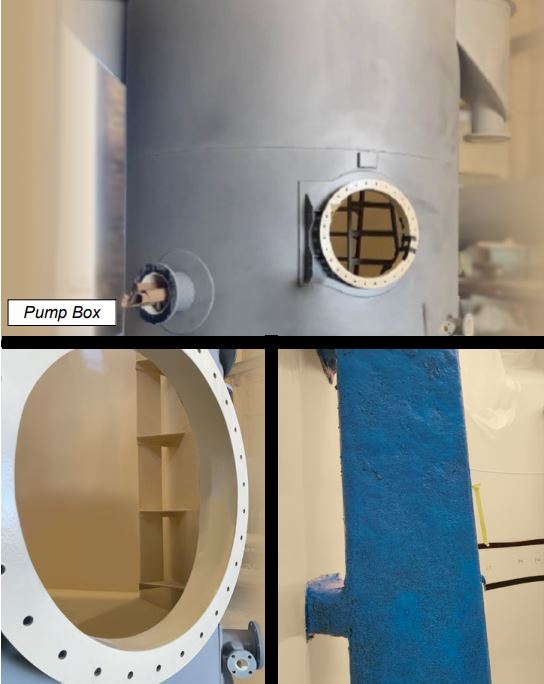

Pump Box with Baffles in potash mine undergoes high-temperature wear, erosion and corrosion. This wear is caused due to continuous exposure to high temperature saline processing solution. As a result, the equipment needs to be pulled offline, cleaned and recoated frequently to repair the damage. In addition, the current process and coating requires the equipment to be moved offsite for a post bake cure, further increasing downtime and maintenance cost.

Process Conditions

• Wet slurry with a consistency of 60% solids

• High salinity concentration

• Temperatures that may reach up to 225°F / 107°C

• Continuous erosive & corrosive wear conditions

Solution

To achieve the desired results, three products including Devcon Wear Guard 300RTC were trialed:

• Competitor A’s product was applied to the baffles of the Pump Box. The product initially adhered to the baffles but suffered catastrophic bond failure within a few weeks of application.

• Competitor B’s product was applied to the interior walls of the Pump Box. The product adhered to the walls but had begun to wear in several spots.

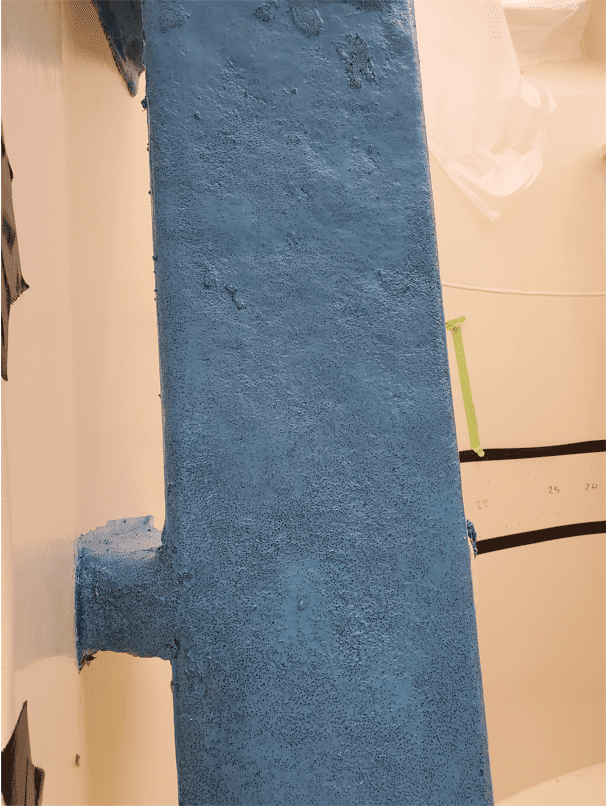

• Devcon Wear Guard 300RTC coating was applied to the baffles of the Pump Box. The coating adhered to the pump box baffles and after 3 months of service had not shown any signs of wear

The Pump Box was inspected at 6 months:

- Competitor B’s product had worn off in numerous spots.

- Devcon Wear Guard 300RTC coating was still adhering to and protecting the baffles.

At 9 months:

- Devcon Wear Guard 300RTC coating showed almost no wear and strong adhesion to the baffles, resulting in superior wear resistant properties.

Results

Devcon Wear Guard 300RTC provides long-lasting protection significantly outlasting competition:

Highly durable coating – 3X longer vs competition

• Equipment is in service longer, increasing uptime and Overall Equipment Effectiveness

• Reduced maintenance and reapplication costs

Cost-effective solution

• Room temperature cure eliminates the need to transport equipment, tenting, portable heaters, and delays due to long cure times

Easy to Apply

• Product is creamy and easy to mix

• Smooth surface finish is achieved by water vs using dry or chemical abrasives

• Sag free application ideal for vertical surfaces

Quick Inspection

• Distinct blue color results in quick assessment of worn-out areas

• Superior protection in harsh environments including high temperature, high corrosion, and caustic environment

Annual Maintenance Expenditure Competitive coating:.................$18,000 Devcon Wear Guard 300RTC:..$4,500 Annual Savings:....................... $13,500