Problem

A mining leader of precious metals & minerals in South Africa was searching for a solution to repair a heavily worked pump moving an ore slurry throughout the platinum mine. The previous solution was a locally produced epoxy wear compound. The competitor product, applied at 12mm thickness, lost its effectiveness of withstanding excessive wear after 4 weeks. As a result, the pump needed to be taken offline and recoated regularly, leading to excessive downtime at the facility.

The customer was looking for a durable coating to protect the slurry pump, as each recoating cost the facility up to 1 ½ days in loss of ore production. The coating needed to be efficient and effective, providing provide long-term protection thereby avoiding frequent reapplication and downtime.

Solution

Devcon Wear Guard 300RTC was chosen for its superior performance in abrasive, wet, chemical saturated environments.

- Initially, a trial test layer of just 6mm thickness of Devcon Wear Guard 300RTC coating was applied. With this successful screening, the customer found that Devcon Wear Guard 300RTC doubled the service life at only half the amount of thickness as compared to the competitor coating.

- Given this successful application, the customer chose to apply 12mm thickness of Devcon Wear Guard 300RTC to ensure 4X the service life vs the previous epoxy wear compound.

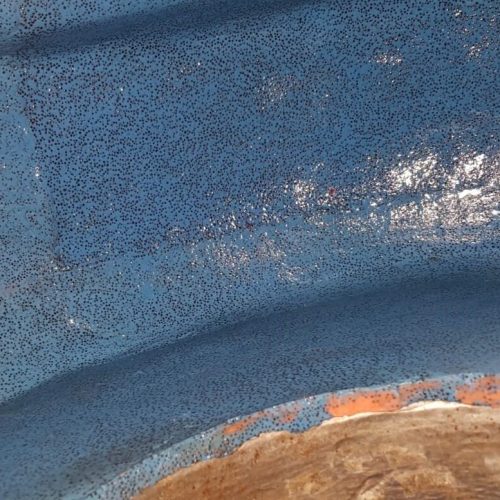

- The corrosion resistant coating was smoothed by hand and with water to give a smooth glass-like surface finish, creating the most ideal sliding properties.

- The repair with Devcon Wear Guard 300RTC was done quickly and easily at room temperature.

Project Outcome

Proven Superior Performance

Devcon coatings are proven to repair and protect damaged equipment. Application of Devcon Wear Guard 300RTC resulted in a durable, long-lasting coating that reduced repair frequency and up to 4-6 days of equipment downtime.

Excellent Mechanical Properties

In addition to superior wear resistance, Devcon Wear Guard 300RTC withstands temperatures up to 300°F (150oC) in both wet and dry environments, has a functional cure between 8-10 hours at room temperature without the need of post-curing. Furthermore, it provides excellent corrosion resistance.

Extends Maintenance Schedule

When compared to other solutions, Devcon Wear Guard 300RTC is succeeding in withstanding abrasive, wet environments while being exposed to various chemicals. The industrial coating doubled the service life of the slurry pump, even when applied at half the thickness.

The easy application and longevity of Devcon Wear Guard 300RTC wear compound allowed the customer to achieve their repair goals and extend their maintenance schedule. In addition, the customer also coated spare pump parts on site with Devcon Wear Guard 300RTC.