In an industry with a countless selection of adhesives categories and capabilities, finding the right glue for specific applications can be an overwhelming task. Whether you’re a hobbyist working on a ceramic project or an engineer searching for the best sealing adhesive for chemical-resistant applications, understanding the properties and competencies of an adhesive is critical. In this blog post, we will dive into the continual evolving adhesive class of MMA (methyl methacrylate) acrylic adhesives and their outstanding chemical resistance properties.

MMA adhesives, also commonly known as acrylic adhesives, are sought out for their outstanding adhesion capabilities across various substrates, making them the go-to choice for many industries. These versatile adhesives are particularly renowned for their exceptional performance in challenging environments such as wide temperature ranges and applications where chemical resistance is a top priority.

Ceramics, with their fragile nature and porous surfaces, can be a challenge to bond. Ceramic glue is critical to many applications. Finding the best glue for ceramic applications is crucial to ensure longevity and durability. MMA adhesives, with their high tensile strength and resistance to chemicals, make them an ideal choice for bonding ceramics. Whether you’re fixing a broken vase or working on intricate ceramic art, MMA acrylic adhesives offer a reliable solution.

The strength and durability of MMA adhesives lies in their acrylic polymer and compound composition. This polymer family forms a durable bond with a wide range of materials, including metals, plastics, composites, coatings, and more. The unique structure of the acrylic polymer allows MMA adhesives to maintain their integrity even when subjected to various chemical exposures.

In applications where a tight, chemical-resistant seal is necessary, MMA adhesives stand out as sealing adhesives. As such, they are able to form a durable, impervious seal and structural joint that makes them an excellent choice for industries such as automotive, aerospace, and marine, where maintaining the integrity of joints and seams is crucial.

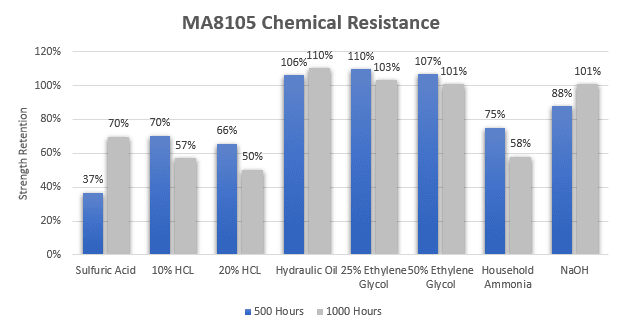

A chemical resistance chart is a valuable resource when choosing the right adhesive for a particular application. MMA adhesives are known for their compatibility with a wide range of plastics, including chemical-resistant plastics. This compatibility ensures that the adhesive will maintain its adhesion strength even in the presence of chemicals.

Acid-resistant MMA adhesives are strong leaders for such resistance, withstanding exposure to acids that many other adhesives would not. Corrosion inhibitors play an important role in chemical resistance in the adhesive industry. Whether you are working in a laboratory, chemical plant, or any other industrial environment where acid resistance is essential, MMA adhesives have a history of performance.

In applications where adhesives are subjected to wear and tear, MMA adhesives still hold their ground. Their exceptional long-term adhesion characteristics mean that they maintain their bond strength even under dynamic mechanical stress and environmental factors. This durability ensures that the bonded components remain intact, or structural in nature for an extended period.

MMA acrylic adhesives are well established performers in the adhesive world when it comes to chemical resistance and durability. MMA acrylic adhesives offer premium performance with their ability to form strong, long-lasting bonds even in challenging environments. Making this class of adhesives an invaluable choice for a diverse and wide range of applications. If you’re faced with a chemical bonding challenge, consider the durable properties of Plexus MMA acrylic adhesives to assure your bonds will stand the test of time.

By: Samantha Gaigals, Application Engineer

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more information like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.