How to Repair, Rebuild & Protect Your Equipment with the Devcon Wear Guard Wear Resistant Coatings

Devcon was founded in the 1950s with a goal of developing products that would provide a safer alternative to welding. Over the years, the Devcon brand has expanded to provide a wide range of high performance wear and abrasion resistant coatings to many industries. One of the most important product groupings developed is the Wear Guard family of wearing resistant coatings. As you will see, these products protect from abrasive wear in many industries.

These innovative wear resistant coating products are geared to:

- Increase Uptime: Minimize equipment downtime with durable coatings.

- Extend Equipment Life: Protect vital components from wear and tear.

- Reduced Costs: Decrease maintenance and replacement expenses.

These coatings excel in harsh environments and are easy to apply, requiring minimal training.

Abrasive wear occurs in many different applications and industries. The Devcon Wear Guard family of products coat equipment and protect them from their extreme conditions. Anywhere you are seeing wear, distortion, or damage, a Devcon wear resistant coating could successfully aid in protecting your equipment.

The Devcon Wear Guard Wear Resistant Coating Product Highlights

- Our first product to discuss is Devcon Wear Guard High Load. This is the work horse of the product family and provides a very easy-to-apply product with strong wear resistant properties. Whether you are applying to a slurry or a dry application, Wear Guard High Load will provide a strong protective coating.

- Versatile for slurry and dry applications.

- Strong wear-resistant properties.

- The Devcon Wear Guard Fine Load has the same benefits of the Devcon Wear Guard High Load, but geared for fine particle applications – so areas that have sand or fine dust abrasion will be better protected with Fine Load. This is due to the unique silica beads that are utilized in the formulation.

- Ideal for fine particle applications (sand, dust).

- Incorporates unique silica beads for enhanced protection.

- With standing heat up to 450°F / 232°C, Devcon Wear Guard High Temp, shows high endurance. Most other abrasion-resistant coatings will fail at such high temperatures.

- Withstands high temperatures.

- Superior endurance in extreme conditions.

- Devcon Wear Guard High Impact has a unique epoxy urethane acrylate hybrid resin system to withstand impact, not just sliding abrasion. This resin chemistry has outstanding fracture toughness.

- Unique hybrid resin system for impact resistance.

- Outstanding fracture toughness for demanding applications.

- Devcon Wear Guard Ultra has outstanding abrasion resistance for severe use conditions.

- Exceptional abrasion resistance for extreme environments.

- The newest epoxy technology in the Wear Guard family, Devcon Wear Guard 300RTC (room temperature cure) protects in wet & dry environments up to 300°F / 149°C

- Room temperature cure, effective in wet and dry environments.

- Operates up to 300°F (149°C).

How to apply

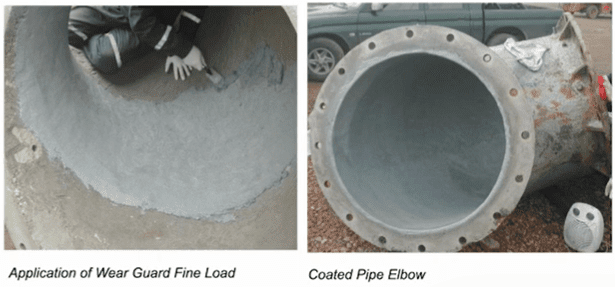

Easy-to-apply wear resistant coatings like Devcon Wear Guard 300RTC, which performs expertly in elevated temperatures, are all applied in the same manner. The main goal is to have a good surface prep: Getting to white metal, establishing a uniform mix, and then from there, you can apply the wear resistant coating by hand or trowel. All products have the ability to be smoothed with either acetone or water, depending on the formulation.

Additionally, we provide a power mixer to aid in the application of product. Mixing these tubs of product can be labor intensive, so this mixer provides a quick mix that ensures the products are thoroughly mixed in a way that is easy for applicators to install.

Remember: To apply these coatings effectively:

- Surface Preparation: Achieve white metal standards.

- Mixing: Uniformly mix products; a power mixer is recommended for efficiency.

- Application: Use hand or trowel for application; smooth with acetone or water.

Common Applications Needing Wear Resistant Coatings

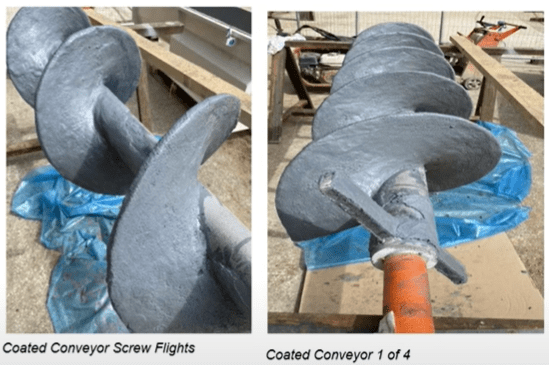

- For our first example, one of the most common applications that need and benefit from the Devcon Wear Guard family are conveyor screw protection. These are pieces of equipment that many companies use to transfer materials throughout their process and these augers experience extensive wear.

It is not uncommon for flights to become damaged over time and these screw conveyors are frequently replaced, which becomes costly. By applying a Wear Guard product such as Devcon Wear Guard Fine Load or Devcon Wear Guard High Load, the equipment life can be extended. With one of our clients, the screws were being replaced every 6 months, but after beginning to apply Devcon Wear Guard protective coatings, the longevity of these screws extended to a full year – doubling the equipment life. Read more on wear resistant coatings for screw conveyors in this case study.

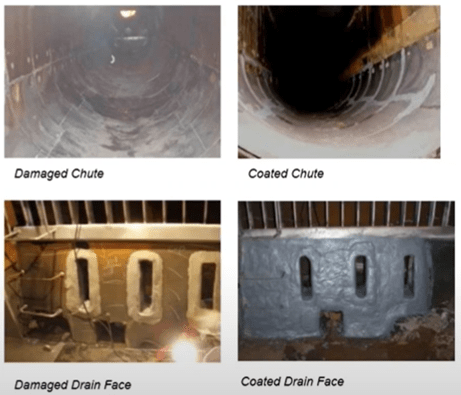

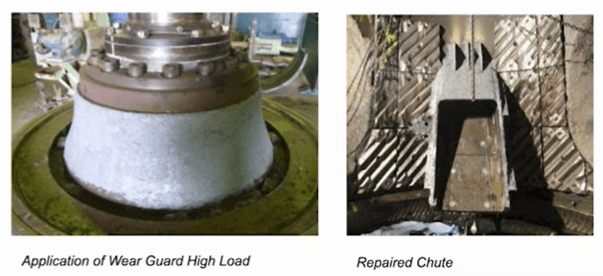

2. The next application that highly benefits from abrasion resistant coating is protecting a drain face. In a processing plant, they had a large chute that ran into a drain face. The tiles & plates in these areas were becoming worn and damaged. To protect the equipment, the surface areas were coated with Devcon Wear Guard High Load and the repairs were completed within one full week.

3. Pipes are another area that frequently see damage from wear. Whether they are damaged from dry abrasion hitting an elbow or oxidation forming within the pipe, they typically need repair and protection from further wear and abrasion. By applying a wear resistant coating of Wear Guard Fine Load, these types of damages can be mitigated fast and efficiently. Read the case study.

4. Our last example is a vertical roller mill requiring repair. With this type of application, there are several areas of damage that can cause concern with engineers. Devcon Wear Guard High Load is a solution that can be applied to many areas and thoroughly smoothed. This provides a quick, durable repair that allows the roller mill to resume operations quickly. Read more on wear resistant coatings for vertical mills.

The Devcon Solution

Devcon’s Wear Guard family of industrial strength epoxy coatings offer products that allow you to rebuild, repair, & protect equipment. These high performing and easy to apply products provide solutions in the toughest conditions. Not only are these durable and innovative products, but they come with a dedicated technical and customer support team who are ready to assist with choosing the correct product for your unique situation. Our global manufacturing & supply networks ensure that ITW Performance Polymers can provide products to you in a quick manner. With over 70 years of proven solutions, we are confident that Devcon can provide you with an answer to your maintenance needs.

For more information or to discuss your specific requirements, reach out to our technical support team today!

Check out the other Devcon® 101 Series blog posts:

- Devcon®101 Series: Wear Resistance with Devcon DFense Blok™

- Devcon® 101 Series: Fast Curing, Wear Resistance with Devcon Coatings

- Devcon® 101 Series: Elevated Temperature Wear Resistant

By: Tony Mell, N.A. Sales Director and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Durability With Devcon® Protective Coatings: Proven In Multiple Industries and The Top Four Types Of Wear Impacting Industrial Equipment.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.