The fly ash by-product in a coal fired power plant is quite hazardous to both humans and the environment. Fly ash is a highly abrasive material, making it often difficult to pump. Therefore, not only do safety measures have to be taken but general maintenance issues must be addressed for effective operations in the plant.

Problem

A fly ash pump at a coal power plant experienced extreme wear due to large particulate slurries flowing through it. The consistent wear caused the fly ash pump to be replaced every three months, costing the facility about $35,000 for each replacement. The high repair frequency significantly increased both downtime and overall maintenance costs at the power plant.

Solution

Devcon Titanium Putty and Devcon Wear Guard™ Fine Load were applied to the fly ash pump to provide protection from extreme wear and abrasion:

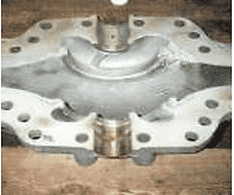

- The repair area was sandblasted to white metal and expandable metal was tack welded 1/16” above the substrate. The area was then cleaned with Devcon Cleaner Blend 300 to rid the surface of grease and oil deposits on metal.

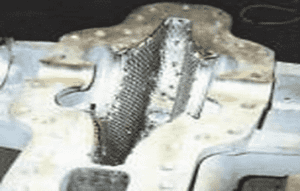

- Devcon Titanium Putty was applied to the flange area, rebuilding the missing metal.

- Devcon Wear Guard Fine Load was applied to the volute to a thickness of ½” to provide wear protection.

- Devcon Wear Guard Find Load applied & feathered using acetone leaving a smooth and contoured finish to the fly ash pump.

Project Outcome

Cost Effective

- The cost to repair the fly ash pump with Devcon coatings totaled $2,000 in comparison to a full replacement cost of $35,000.

- With Devcon Wear Guard Fine Load coating, pumps can be consistently repaired, rebuilt, and returned to service vs replacing equipment every three months.

Highly Durable Coatings

Devcon Wear Guard Fine Load and Devcon Titanium Putty protect the pump from the extreme abrasion created by the large particulate slurry prolonging the pumps overall service life.

Smooth Application

Both the Devcon Titanium Putty and Devcon Wear Guard Fine Load are smooth and easy to mix requiring little to no safety equipment or PPE.

Devcon Wear Guard Fine Load & Devcon Titanium Putty coatings repaired and rebuilt the fly ash pump saving the coal plant $33,000 by avoiding fly ash pump replacement.