Manufacturers of buses, from double-deckers, single-deckers and mini-buses, are required to cope with a large number of daily commuters, ensuring they retain their durability and reliability over the typical 10-15 year life span.

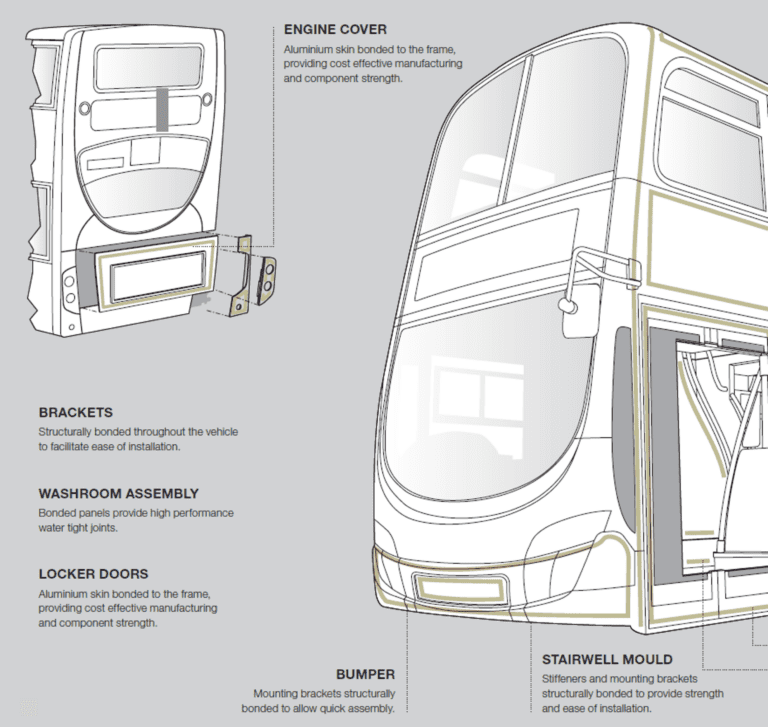

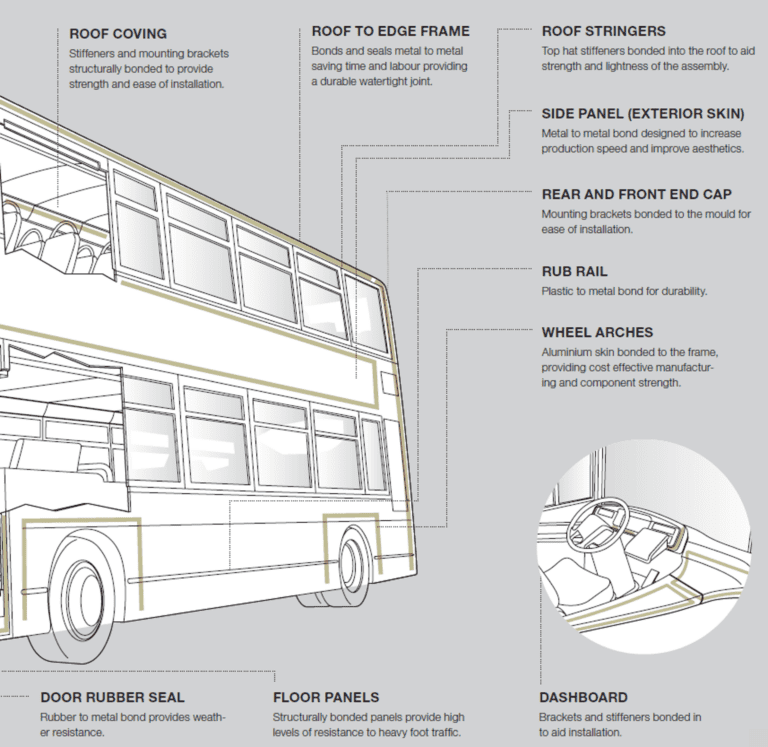

We work closely with bus manufacturers to provide reliable fixtures for all challenging applications, including high liability assemblies such as front and rear end caps, internal moldings and dashboard assemblies.

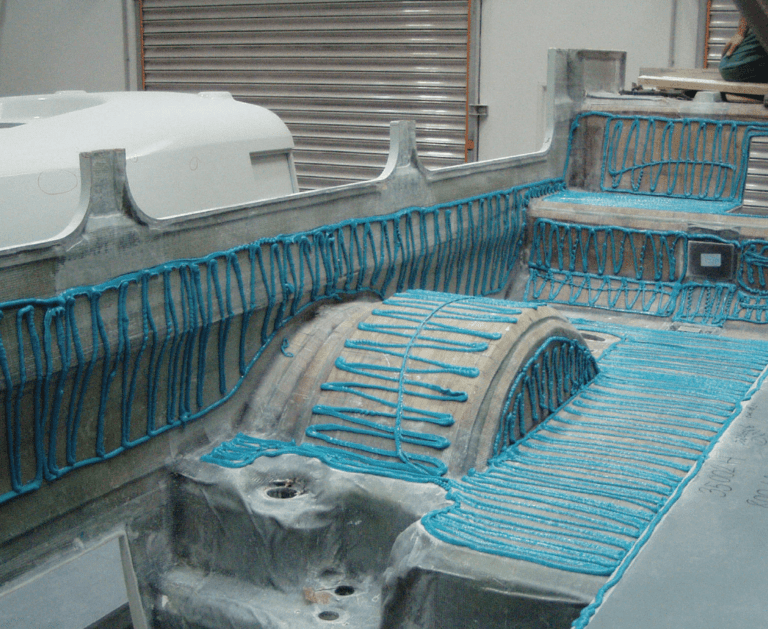

Plexus structural bonding adhesives offer high strength with minimal surface preparation, therefore streamlining the production process. The unique characteristics of our structural bonding adhesive systems allow bus manufacturers to replace welding structures, reduce distortion and post weld dressing, and improve fatigue performance.

Plexus provides customers with confidence in the strength and reliability of our structural bonding adhesives. In addition, Plexus has contributed to the development and manufacture of low carbon buses, as bonding with GRP / FRP has allowed manufacturers to reduce weight and improve fuel efficiency.

PRODUCT BENEFITS INCLUDE:

- High structural strength

- High impact resistance

- Reduced VOC emissions

- Excellent fatigue resistance

- Easy to use, no specialized training required

BENEFITS OF BONDING WITH PLEXUS:

- Improved production speed by efficient processing and quick cure

- Improved aesthetics of the finished vehicle

- Wide range of open and fixture times available to suit all applications

- More design options and substrate choice: Ability to bond dissimilar metals and materials

- Bond lines designed to withstand climatic stresses and different environmental conditions

- Lower component costs, due to the ability of adhesives to bond to a wide variety of different substrates

- No need for rivets, therefore significantly reducing load individual stress points and the evenly distributing the load

- Avoid corrosion: No need to drill or pierce substrates for mechanical fastening

The bus illustrations below demonstrate where Plexus structural bonding adhesives can be applied. The bonding solutions are easy to use and fast fixture times meet production and process requirements.

Plexus Structural Bonding Adhesives for Buses

- Next generation primerless multi-material adhesive

Plexus MA8110 GB and MA8120 GB

- Fastest primerless to metal adhesive

- Primerless to metal adhesive

- Primerless to metal adhesive – medium open time primerless

- All-purpose toughened adhesive

- Excellent low temp impact, white UV stable

By: Kry Wesselink, Product Manager EMEA and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.