Introduction

Structural adhesives have become a popular choice for metal to metal bonding applications due to their ability to distribute stress evenly across a joint. This is especially important in applications where the bond is subjected to heavy loads or stress. Let’s explore the benefits of using structural adhesives in metal to metal bonding applications and how they can help to distribute stress more effectively.

Structural Bonding

When metal bonding, it is important to consider the types of forces to which the joint will be subjected. These forces can include tensile, compressive, and shear forces, as well as thermal and dynamic loads. In traditional metal joining methods, such as welding and bolting, the joint is often weaker at the point of connection, which can cause stress concentration and lead to fatigue, and ultimately failure under heavy loads. Additionally, mechanical fasteners tend to loosen under dynamic loads or vibration. In contrast, structural adhesives can distribute stress evenly across the entire bonded surface, creating a strong and durable joint.

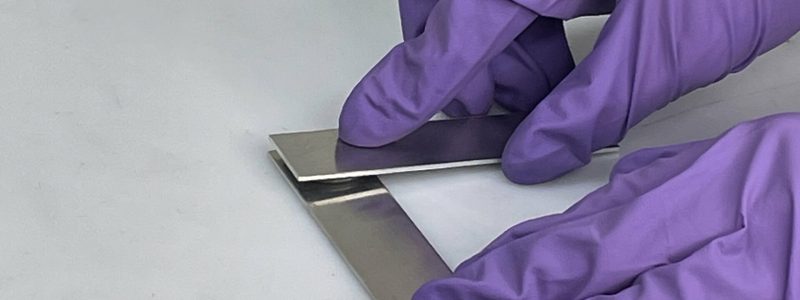

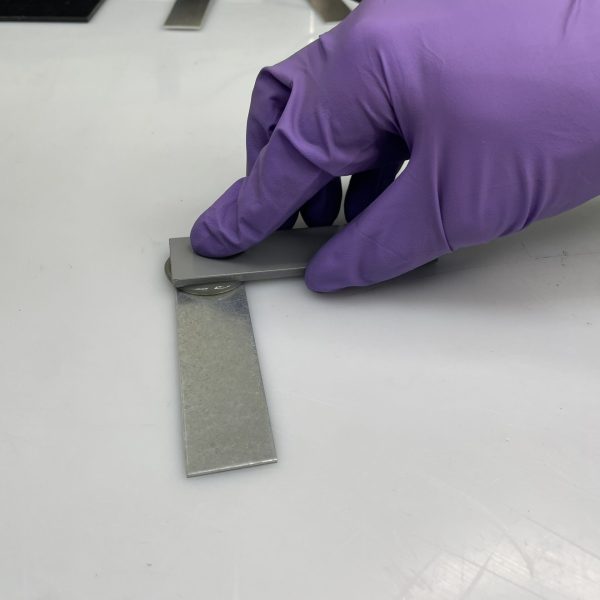

Adhesion Bond

Plexus® methacrylate structural adhesives are formulated to provide exceptional bonding strength and durability, and are extremely fatigue resistant, through the use of Plexus’ impact absorbing core-shell technology. In addition, Plexus MMAs can be used on bonded structures and to bond a wide range of metals, including aluminum, stainless steel, cold-rolled steel and others, making them a versatile solution for many different applications. The recently introduced Plexus 8100 series of 1:1 methyl methacrylate adhesives provide primerless bonding to aluminum and galvanized steel, reducing manufacturing steps and costs for surface preparation materials. There are many benefits to a good metal adhesive.

Additional Benefits to Metal Bonding

Another benefit of using structural adhesives is that they can help to reduce weight and increase fuel efficiency in many different industries. For example, in the transportation and automotive industry, bonding metal parts with structural adhesives can help to reduce the weight of vehicles, leading to lower fuel consumption and operating costs. Electric vehicles take advantage of these properties as lower weight translates into greater vehicle range per charge. In addition, the use of structural adhesives in automotive applications can help to reduce the wear and tear on vehicle components, including composite structures, improving their lifespan and reliability.

Structural adhesives can also help to improve the aesthetics of metal to metal bonding applications. Unlike traditional joining methods such as welding and bolting, structural adhesives can create a clean and seamless bond that is free of visible fasteners or welds. This can improve the overall appearance of the finished product, which is especially important in applications where aesthetics are important, such as in the construction of high-end consumer products or architectural structures.

To ensure that structural adhesives are applied correctly and effectively in metal to metal bonding applications, it is important to follow the manufacturer’s instructions and use the proper application techniques. This may include surface preparation, proper mixing and dispensing of the adhesive, and appropriate curing times and temperatures. In addition, it is important to select the right adhesive for the specific application, taking into consideration factors such as the type of metals being bonded, the load and stress requirements (prevent CTE mismatch), and the operating environment. If working in hot areas, select a high temperature adhesive to prevent application errors Sometimes glass beads are added to formulation, such as the Plexus MA8100 series of 1:1 MMA adhesives, as well as the MA800 series of 10:1 products.

Conclusion

By using structural adhesives, manufacturers can create strong, lightweight, and aesthetically pleasing products that are capable of withstanding extreme stress and loads. Whether bonding parts of an electric car or bonding trailer parts, Plexus structural adhesives have a lot to offer your team.

By: Kry Wesselink, Product Manager EMEA and Sarah Vigue, Marketing Specialist

Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more information like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.