Post Takeaway:

To understand how much time is needed before Chockfast becomes hard, what items will affect this process, and what are best practices to plan for this process.

Outline

- Introduction

- Pot Life vs. Cure Time

- Initial cure vs Full Cure

- Effects of Temperature

- Implications for the Installer

Different Cure Stages of Chockfast

In our last blog post Explaining the Epoxy Cure Cycle of Chockfast® Epoxies, we explored how Chockfast cures, transforming from a liquid into a solid. This blog edition dives deeper into the different epoxy chocks and epoxy grout cure stages associated with the Chockfast product line.

How Long Do I Have to use the Mixed Material? Understanding the Effective Time to Install Chockfast

Pot Life, also known as Working Time, is the period between start of mixing the liquid components and when they start to solidify. This industrial epoxy timing (reaction) is the window you have to pour and place the material effectively. Each Chockfast product measures and lists its respective Pot Life at around 70°F (21°C) in the Technical Data Sheet. Epoxy Chocking compounds like Chockfast Orange, Gray, and Black have Pot Life ranges from approximately 30 to 45 minutes at 70°F (21°C). Similarly, Epoxy Grouting compounds such as Chockfast Red, Chockfast Red Versaflow, and Escoweld 7505E/7530, display their Pot Life’s at about 2 to 3 hours, also at 70°F (21°C).

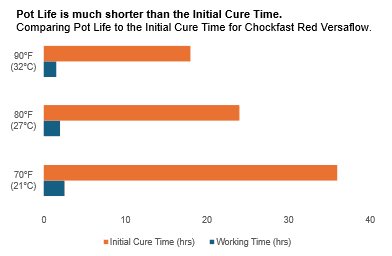

The epoxy grout pot life is influenced by the ambient and mass temperature during installation, including both the material and the installation area. Like all two-part reaction chemistries, higher temperatures speed up the reaction, shortening the Chockfast working times, while cooler temperatures slow down the reaction, extending it. Figure 1, shows this relationship using Chockfast Red Versaflow as an example.

Pot Life differs from cure time, which is the duration or period of time needed to develop their strength. Although Chockfast products stop flowing and start to solidify at the end of the Pot Life, they actually take several more hours to achieve their full-strength physical properties. This is also shown in Figure 1.

Initial Cure vs Full Cure (or Final Cure)

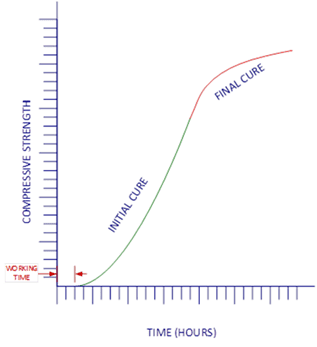

Chockfast epoxy chocks and grouts, like Chockfast Orange and Chockfast Red, gain strength over time, similar to cement-based technologies. However, epoxy-based chemistries provide a much more rapid initial strength gain over cementitious types. The Initial Cure Time, as seen in the various Chocks and Grouts technical data sheets, is considered the minimum recommended waiting period before removing formwork, alignment devices, tensioning anchor bolts, and starting machinery. This period of time corresponds to about 60-80% of the full strength published also at a room temperature of approximately 70°F (21°C).

Final Cure Time, is the time required to reach the product’s full, ultimate physical properties, with the most important often being compressive strength (e.g., 15,250 psi or 105.1 MPa for Chockfast Red). This can vary from a few days to several weeks, influenced by factors like ambient temperature, peak exothermic temperature, installation size, and mounting surface configuration. Figure 2 shows this relationship.

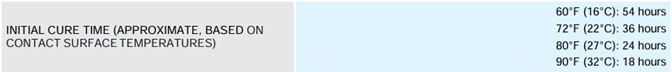

Like Pot Life, Cure Time is affected by ambient temperature. Each Technical Data Sheet includes a range of times based on temperature. As long as the temperature doesn’t drop significantly below the listed value, the material will complete the initial cure cycle within the provided time. Figure 3 is an example from the Chockfast Red Technical Data Sheet showing the initial cure time, which can be found along with the SDS on the Chockfast Red Product page.

As a general rule, if the material temperature stays above 72°F (22°C), Chockfast Red installations will complete their initial cure within 36 hours. If the temperature drops by more than approximately 4°F (2°C), it’s recommended to wait 54 hours for the initial cure to complete.

Implications for the Installer

Remember, the clock starts as soon as the Part B – Hardener is added to Part A – Resin. With this in mind, it is recommended to not mix the components until everything for your pour is ready, including cleaning mounting surfaces and constructing formworks. Always understand the expected curing conditions for the epoxy grout installation and make sure that the temperatures of the material and installation area are within the recommended proper range. Plan to keep the temperature above 55°F (13°C), as the chemical reaction slows down below this. For more information, refer to our blog on Installations in Cold Weather.

Curing Conditions for Epoxy Grout

Proper curing conditions are critical to ensure that Chockfast epoxy grout achieves its designed strength, durability, and dimensional stability. Consider:

- Temperature (ambient and substrate/material temperature)

- Ventilation

- Time (allow sufficient time for initial cure and full cure)

- Protection (during cure, protect the grout from vibration, impact, freezing temperatures, or water exposure)

- Also consider the foundation setting time: This refers to the period required after pouring Chockfast epoxy grout before the foundation can safely support equipment and be subjected to further work or loading. This timing is primarily influenced by:

- Grout type (e.g., Chockfast Red Versaflow, Chockfast Red, or Chockfast Gray)

- Ambient and substrate temperature

- Grout depth and volume

Final Thoughts

For optimal results, visit our website (itwpp.com) and our Assets Library to find and refer to our range of technical datasheets/guides (TDS) on Chockfast epoxy application and curing time & temperature specifics, mixing and pouring guidelines, and more about epoxy grout chemical properties.

If in doubt, contact Technical Services for additional advice on understanding the reaction profiles of Chockfast products (construction adhesives) or effective planning for the cure time. Proper planning ensures high-quality installations and long-term equipment reliability.

By: Christopher Matthews-Ewald, Senior Applications Engineer

To discuss how long you have to place Chockfast precision epoxy grouts or chocks or any of our heavy machinery installation adhesives, please contact ITW Performance Polymers Technical Services or your local Chockfast Worldwide Distributor Network representative.

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Cheat Sheet: Chockfast® Epoxy Grout Typical Installation Steps and Critical Machinery Installation In Cold Weather? Find Out How To Plan For Success.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.