The durability of bonded components is especially important when dealing with large numbers of daily commuters and travelers. At the forefront of innovative design, trains and carriages need to offer long-term, consistent reliability, safety, and optimal operational performance.

When using Plexus methacrylate structural adhesives, manufacturers can assemble sub-components quickly and efficiently when applying modular and piece assembly methods to production. Removing the need for mechanical fasteners can provide manufacturers with lower weight solutions and increased design freedom.

Plexus methacrylate structural adhesives have the ability to bond multiple types of plastics, metals and composites, helping to lower component costs or improve safety, which is invaluable to the rail industry. Plexus methacrylate structural adhesives are used from design to assembly, ensuring structural and secondary components remain intact and resistant to dynamic environmental stresses. Our unique adhesives offer distinct advantages when dealing with complex components and large surface areas.

Plexus methacrylate structural adhesives MA300, MA310, MA420, and MA832 comply with R1 requirements for Hazard Levels HL1 – HL3, across all design and operational categories of rail vehicles.

R1/ Part 2 of EN45545-2:2013 standard for:

- Toxicity – EN45545 Annex C (ISO 5659)

- Flammability (ISO 5658-2)

- Heat Release (ISO 5660-2)

PRODUCT BENEFITS INCLUDE:

- UV stable

- Reduced VOC emissions

- High strength and durability

- Excellent resistance to salt spray

- Ease of use, no specialized training required

- Resistance to fuel, screen wash and other commonly used chemicals

BENEFITS OF BONDING WITH PLEXUS:

- Improved aesthetics and aerodynamic efficiency

- More design options due to the ability to bond dissimilar metals and materials

- A wide range of open and fixture times available to suit all applications

- Bond lines designed to withstand climatic stresses and different environmental conditions

- Easier recycling: No need to cut out the joint and is fully regrind compatible

- Avoid corrosion: No need to drill or pierce substrates for mechanical fastening.

- Reduction in the final weight of the assembly

- Improved efficiency and reduced emissions

- No need for mechanical fasteners

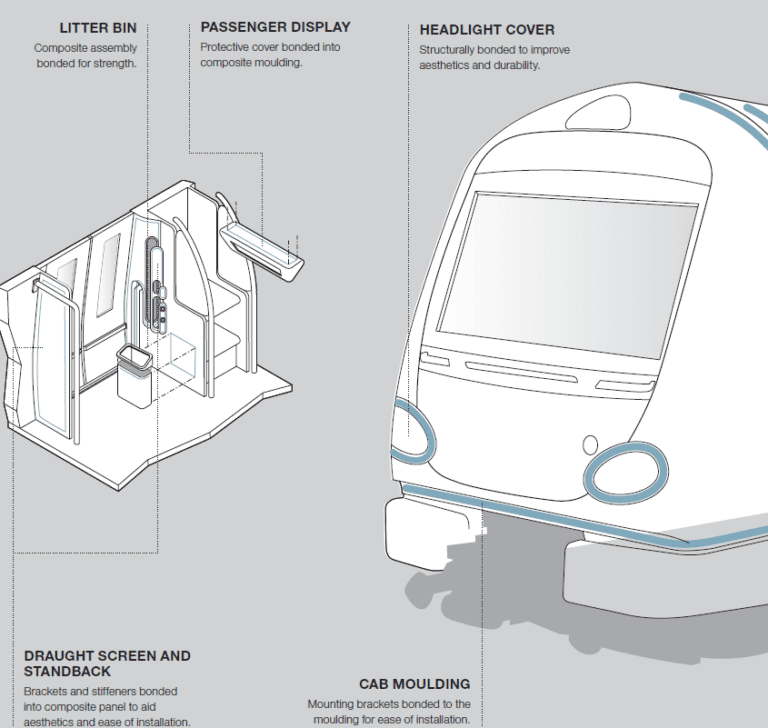

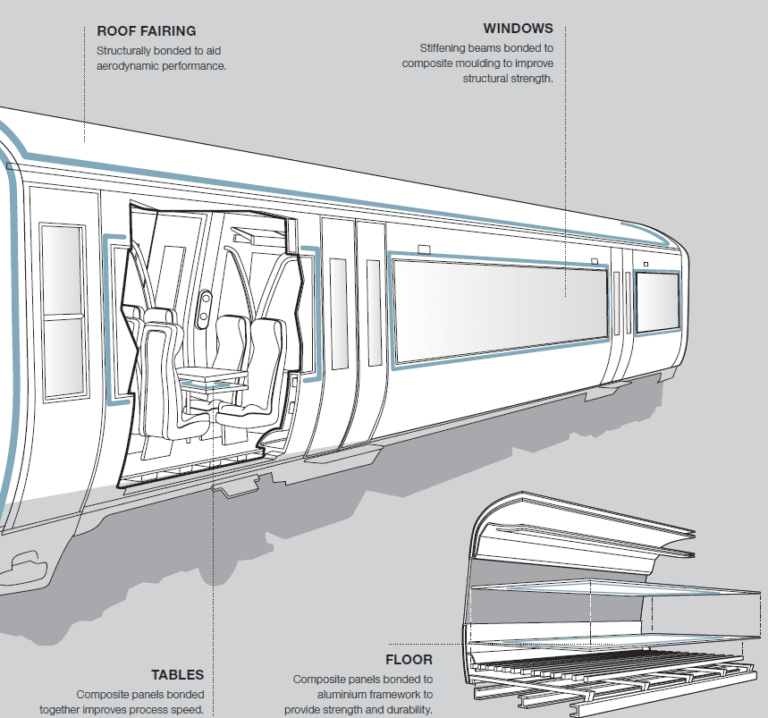

The following train illustrations demonstrate key joining areas where Plexus methacrylate structural adhesives are or can be applied. Our adhesive solutions are suitable for bonding a wide range of substrates including metals, coatings and plastics.

Plexus Structural Adhesives for Bonding Trains

- Next generation primerless multi-material adhesive

Plexus MA8110 GB and MA8120 GB

- Fastest primerless to metal adhesive

- Primerless to metal adhesive

- Primerless to metal adhesive – medium open time primerless

- All-purpose toughened adhesive

- Excellent low temp impact, white UV stable

By: Kry Wesselink, Product Manager EMEA and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.