Global carbon emission standards are becoming more stringent and are an increasing challenge in manufacturing and final product designs, especially for truck manufacturers. Plexus branded methyl methacrylate adhesives can help reduce the overall weight of the vehicle helping with fuel milage and subsequently reduced emissions.

Working in partnership with design and OEM engineering teams, ITW Performance Polymers with its Plexus brand adhesives seeks to lead in the development and use of new structural adhesive solutions and methods. Plexus specialists can be involved in the process from the original design stage to ensure a seamless transition to a bonded solution.

Plexus methyl methacrylate adhesive solutions have proven superior bonding performance, coupled with cost efficiency in the manufacturing process. Plexus can be applied to a wide range of truck bonding applications to ensure durability and reliability with minimal disruption.

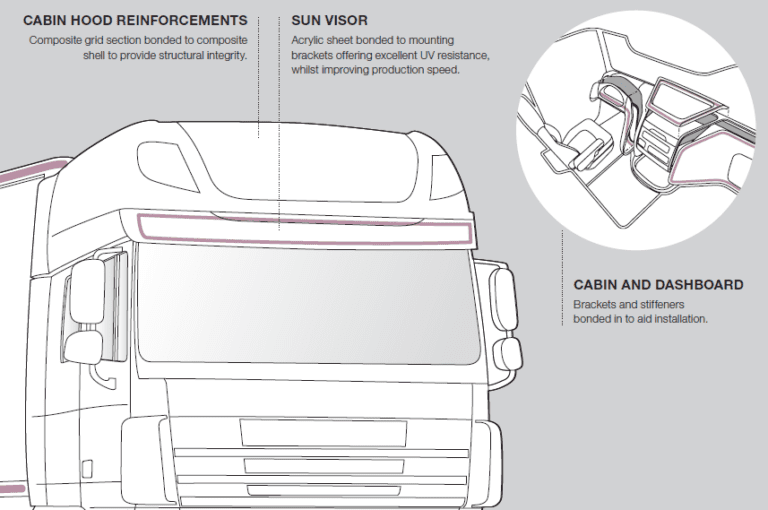

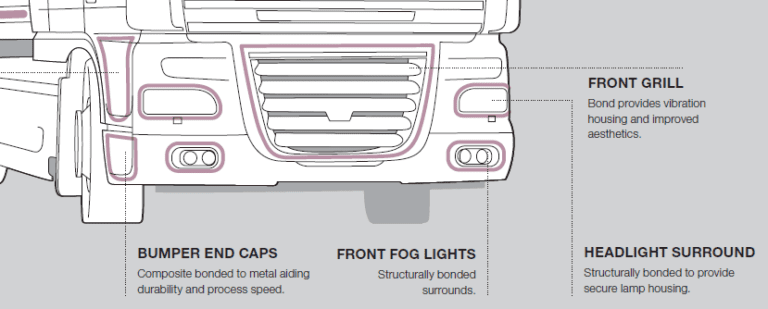

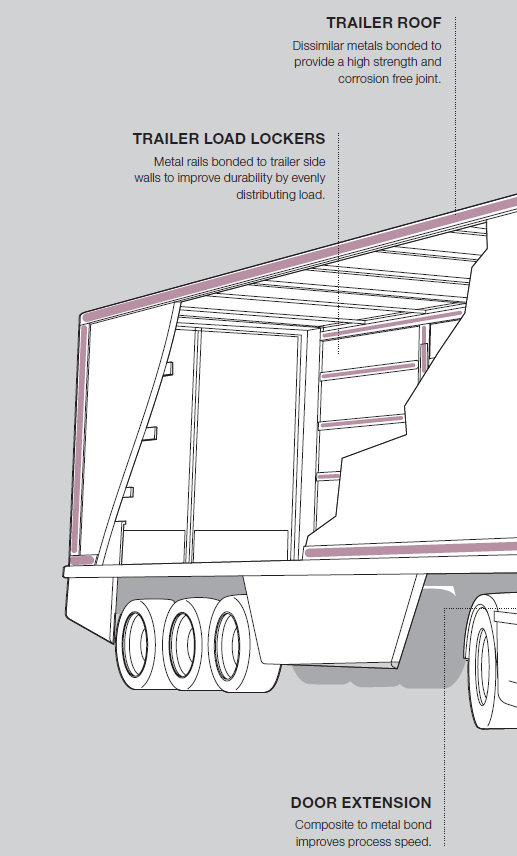

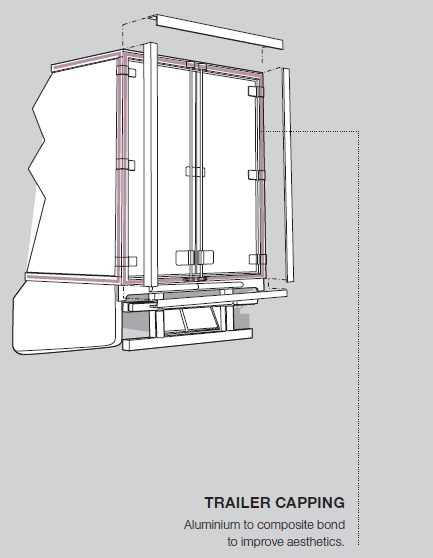

Our methyl methacrylate adhesives are a superior and practical alternative to traditional truck manufacturing methods and are approved by many Heavy Truck Manufacturers worldwide, including Peterbilt & Kenworth. The solutions are ideal for high liability truck assemblies, such as exterior trailer cappings, bumper assemblies, door extensions and exterior sun visors.

PRODUCT BENEFITS INCLUDE:

- UV stable

- Reduced VOC emissions

- High strength and durability

- Excellent resistance to environmental influences

- Ease of use, no specialized training required

- Resistance to fuels, screen wash, and other commonly used chemicals

BENEFITS OF BONDING WITH PLEXUS:

- Improved aesthetics and aerodynamic efficiency

- Increased design freedom due to Plexus’ ability to bond dissimilar metals and various materials

- A wide range of open and fixture times available to suit all applications

- Reduced isolated stress points create by mechanical fasteners including welding

- Easier recycling: No need to cut out the joint and is fully regrind compatible

- Avoid corrosion: No need to drill or pierce substrates for mechanical fastening

- Assist in the reduction in the final weight of the assembly

- Improved efficiency and reduced emissions

- No need for mechanical fasteners

The truck illustrations highlight where Plexus methyl methacrylate adhesives are used to bond many different substrates with little or no surface preparation.

Plexus Methyl Methacrylate Adhesives for Truck Bonding

- Bond E-Tracks, walls to rails, galvanized coated parts, and reinforcements

Plexus MA8110 GB and MA8120 GB

- Composite shiplap bonding, aluminum weld replacement

Plexus MA205HV and Plexus MA830

- Aluminum rail to wall bonding

- All-purpose toughened adhesive

- Excellent low temp impact, white UV stable

By: Kry Wesselink, Product Manager EMEA and Sarah Vigue, Marketing Specialist

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more stories like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.