Many modern-day manufacturers have switched from traditional fastening methods to structural acrylic adhesives and for good reason. From automotive manufacturing to industrial OEM applications, the reliance on bonding glue to create durable and long-lasting bonds is of great importance. Within this realm, methyl methacrylate (MMA) acrylic adhesives stand out for their exceptional fatigue resistance, especially in applications such as lap joints, where shear strength and bonding durability under stress load are critical.

Methyl methacrylate based acrylic adhesives, a class of structural adhesives, have earned their strong reputation for their remarkable bonding strength and structural adhesive properties. Unlike traditional fastening methods like welding or mechanical fastening, adhesive bonding offers a more uniform distribution of stress across the joint, resulting in improved durability cosmetic enhancement and increased longevity under various loads. The distribution of stress across the surface is critical for a long-lasting bond for applications subject to vibrations and a range of stresses.

Lap Joints

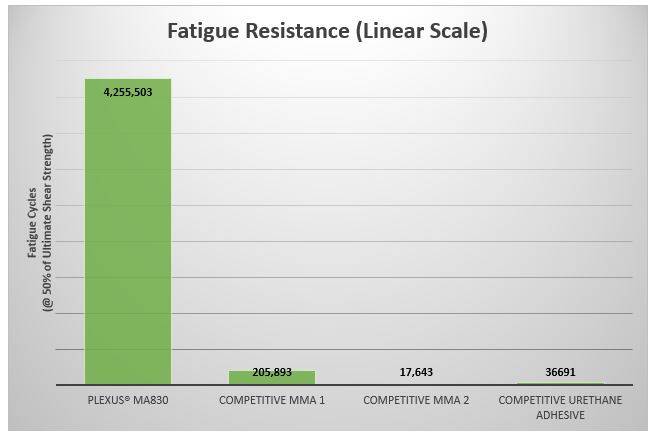

One area where MMA acrylic adhesives excel is in their shear strength and higher peel resistance over other adhesive types. A lap shear joint (or “lap joint”) is the most common across all industries ranging from automotive to marine, where the application requires a durable and strong bond able to withstand shear forces and cyclic loading. MMA adhesives provide excellent adhesion in lap joints, ensuring structural integrity even under ever-changing conditions. The resiliency of MMA adhesive allows these joints to support loads, both big and small, with great strength retention making them great options for applications that require high fatigue resistance.

Shear Strength

The shear strength is one of the most developed, defined, and well-rounded qualities of acrylic adhesives. Shear strength refers to the ability of an adhesive bond to withstand forces parallel/in line to the surface of the bonded materials. In structural bonding applications, where components are exposed to dynamic loads and vibrations, high shear strength and peel resistance are essential for the strength retention of the bond over time. MMA adhesives demonstrate superior shear strength compared to other adhesive options, making them ideal for applications where durability is important.

The durability of MMA adhesives under dynamic loads is a testament to how durable acrylic adhesives are. Whether in automotive assemblies enduring constant road vibrations or in speed boats exposed to vibration as well as high, continual impact forces over the water, MMA adhesives provide reliable performance over a products life. The great strength retention of acrylic based adhesives in the face of cyclic loading contributes to the longevity and safety of bonded structures.

Overall, the fatigue resistance of MMA adhesives makes them unbeatable in structural bonding applications where durability, shear strength, and bond longevity under dynamic stress loads are critical. As industries continue to push the boundaries of innovation and efficiency, MMA adhesives demonstrate the power of adhesive technology creating robust and reliable bonds that withstand the unpredictable lifetime of the application.

By: Samantha Gaigals, Application Engineer

View all our Technical Data Sheets and Safety Data Sheets. Need some help? Ask a technical question and find a solution!

Further reading: Thixotropy, Viscosity and Rheology … Oh my!, What is fixture time anyway?, and Is it strong enough?.

For more information like this, follow ITW Performance Polymers on LinkedIn and sign up for enewsletter in our website footer.

ITW Performance Polymers is an international leader in structural adhesives, grouting and chocking compounds, and wear-resistant coatings and repair products. Contact us to learn more about these products and their applications.