ADHESIVES - AUTOMOTIVE

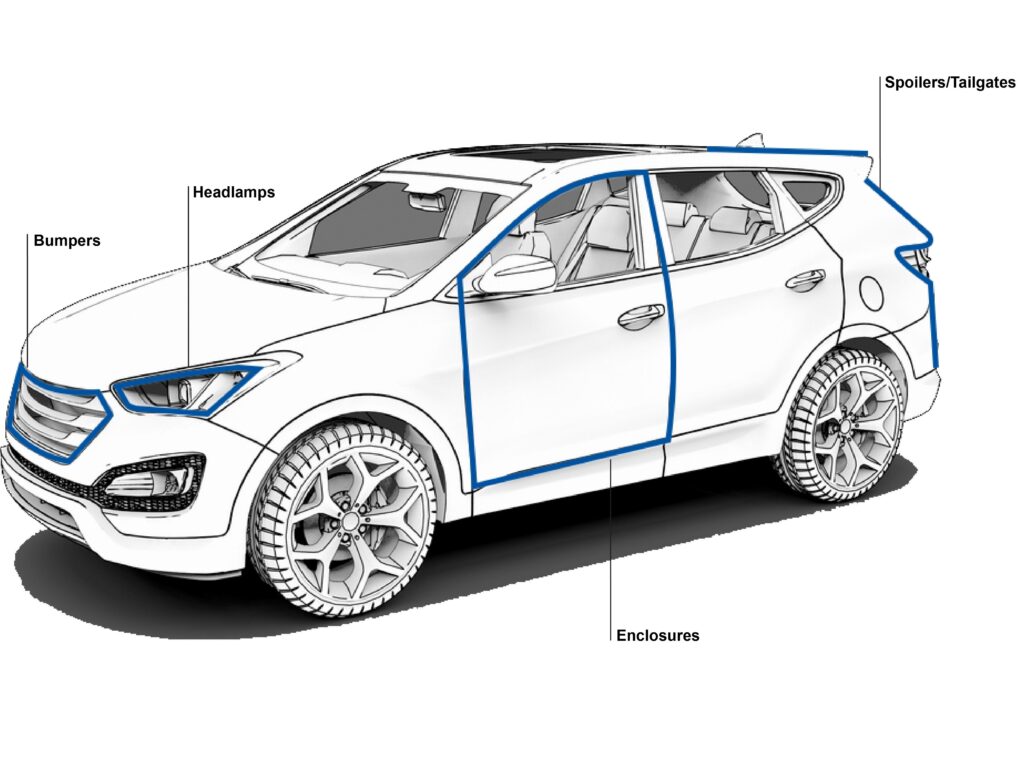

Automotive engineers can reduce tooling cost by using Plexus adhesives. Less complex fixtures can be used due to the fast room temperature curing of Plexus. As regulations concerning fuel economy and electrification evolve, ITW’s Plexus brand continues to develop unique tools for lightweighting and improved fuel economy. The high strength & elongation properties of Plexus adhesives allows bonding of mixed materials, such as joining aluminum to steel, or joining polyamide (nylon) to aluminum.

Features

- Fast room temperature cure

- Superior fatigue resistance

- Excellent environmental resistance

- Primer-less adhesion to multiple materials

Benefits

- Enable light-weight materials

- Mixed material bonding

- Tight dimensional tolerances

- Lower capital costs

- Lower operating costs

Substrates:

Applications:

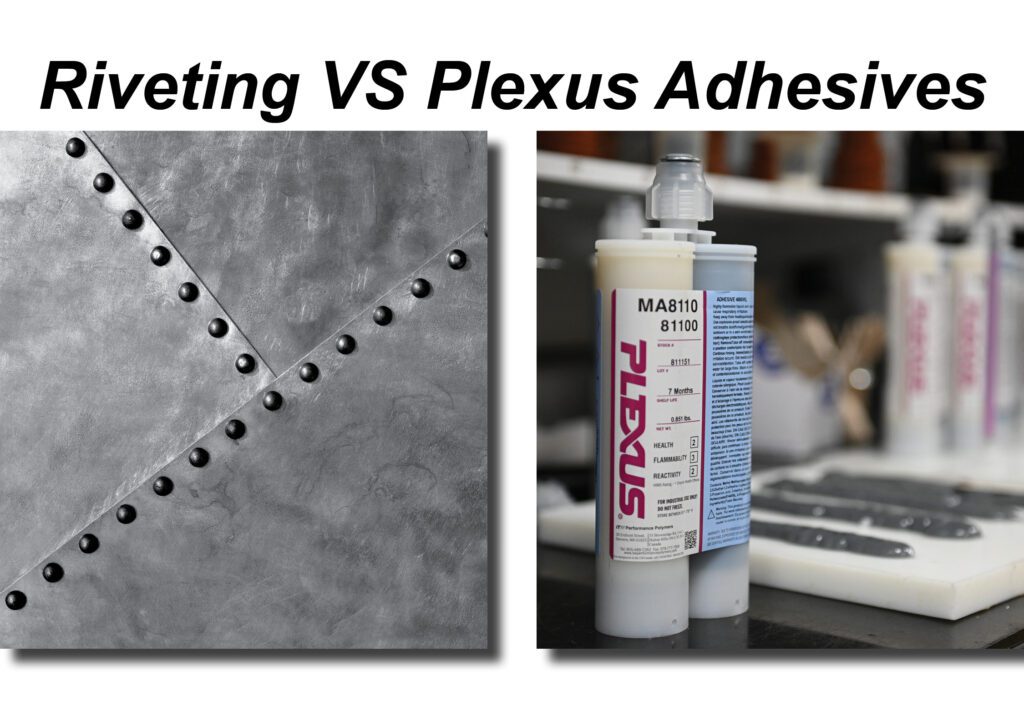

Improve Throughput!

Optimize your assembly process and production throughput with Plexus Adhesives!