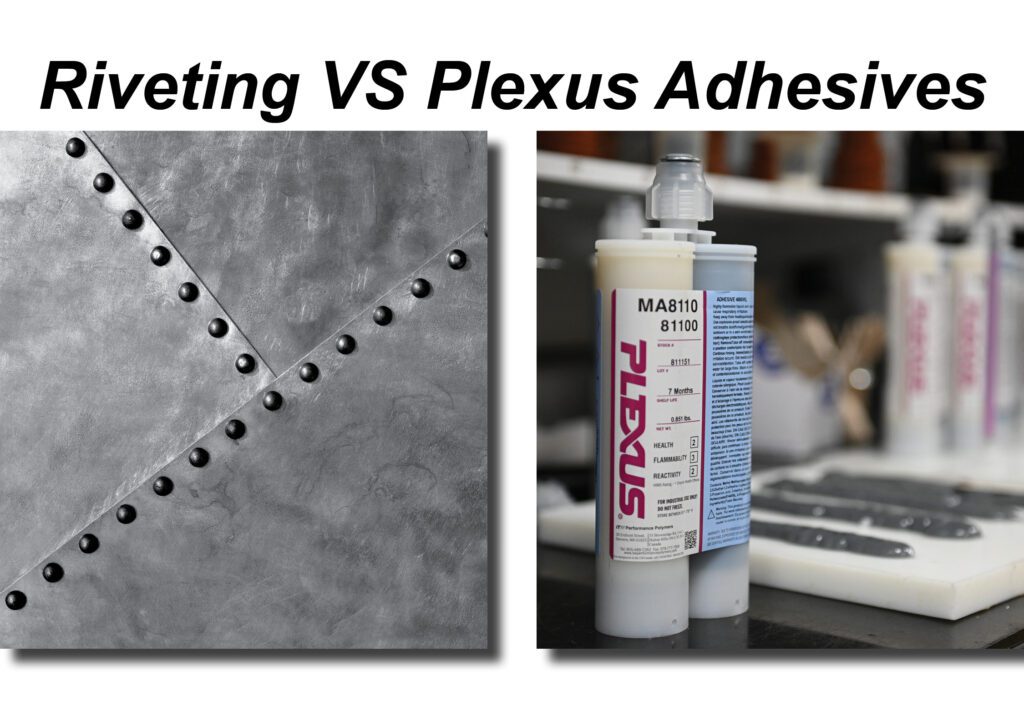

PLEXUS ADHESIVES - BUS

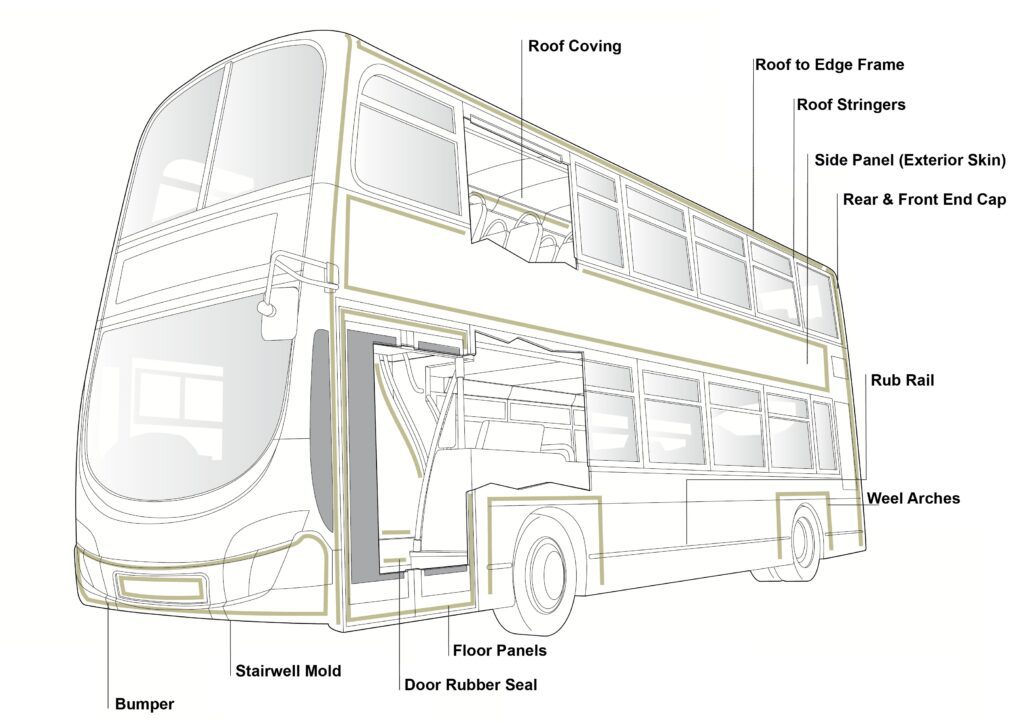

Buses have rigorous requirements in many categories like safety and durability. Plexus adhesive solutions help bus manufacturers with tools for lightweighting and improved durability. Primerless adhesion allows joining composite to metals, permitting design engineers to try new solutions for next generation buses. Assembly workers appreciate how easy Plexus adhesives are to use; its clean, sag-free and fast application properties, and the wide-range of working times available for jobs large & small.

Features

- Fast room temperature cure

- Excellent environmental resistance

- Superior fatigue resistance

- Primer-less adhesion

- High strength and high elongation

- Thixotropic

Benefits

- Higher vehicle fuel or EV range due to lower mass

- Reduced cost of assembly

- Improved durability

Applications:

Assembly Optimization:

Substrates:

Improve Throughput!

Optimize your assembly process and production throughput with Plexus Adhesives!