In the petrochemical industry, facilities handle many hazardous and nonhazardous chemicals, which (if not handled properly) can cause detrimental effects to the environment and to the health of employees. With safety being a prominent concern, dynamic environmental regulations, and possible government shutdowns, preventive maintenance plans are important in considering all options to mitigate failures and potential exposure to chemical hazards.

Problem

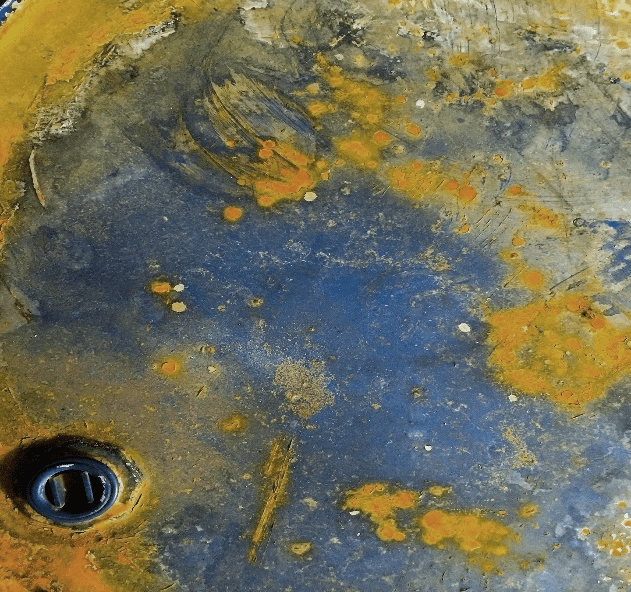

An external tank containing 50m³ (1765 ft³) of sodium hypochlorite (bleach) began to leak in a petrochemical facility putting the health and safety of plant employees at risk. Due to the hazardous nature of the chemical leak, the tank required an immediate repair to limit any spillage of this volatile material. In addition, the external surface of the tank that needed emergency repair was located outdoors and thus exposed to varying climate conditions.

Solution

To prevent a chemical hazard situation, Devcon Devweld 531 and Devcon Flexane 80 Putty were used to effectively repair the chemical leak.

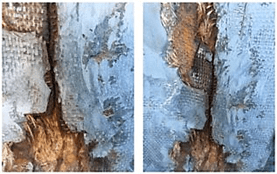

- To prime the surface for repair, the damaged and corroded portions of the tank were removed.

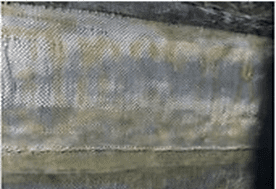

- Devcon Devweld 531 was applied to the surface, fiberglass tape was placed over the Devweld 531 embedding the glass in the Devweld 531. Devcon Devweld 531 was able to provide required adhesion to the nylon material coating the tank.

Devcon Flexane 80 Putty was then applied to the top of the fiberglass tape. The Flexane 80 Putty was molded by hand with a putty knife to ensure a smooth surface coating.

Project Outcome

Quick Installation Preventing Hazardous Conditions

- With Devcon Flexane 80 Putty and Devcon Devweld 531 coatings used together, an immediate potential larger hazard and exposure was contained within just a few hours.

- By quickly and efficiently containing this hazard, safety in this coal plant was effectively maintained.

Highly Durable Coating

The durable, emergency tank repairs now have the ability to hold hazardous material and withstand environmental hazards until the next planned shutdown or scheduled preventive maintenance.

Limiting Equipment Downtime

Devcon Flexane 80 Putty and Devcon Devweld 531 provided an effective and less time-consuming alternative to obtaining a hot work permit or emptying the tank itself.

Devcon Devweld 531 is a successful replacement to welding, providing excellent adhesion to normally difficult-to-bond materials such as nylon, alloys, and polyesters. Devcon Flexane 80 Putty is a fast, easy to use product. These highly durable coatings help keep equipment running safely and smoothly thereby increasing plant uptime and productivity.