Petrochemical manufacturing involves the refinement of crude oil to yield ethane, butane, and propane. However, before this crucial step, crude oil must be washed of its naturally occurring contaminants, to ensure a high-quality output.

One of the most common ways these contaminants are removed is through addition of sulphuric acid to crude oil. Sulphuric acid is a highly corrosive chemical, which (if not handled properly) can cause safety hazards and put an abrupt stop to plant operations. To prevent a safety emergency, secondary containment areas are installed around the equipment to avoid acid leaks and spills.

Problem

At a petrochemical plant, the structural integrity of a concrete secondary containment area was threatened by sulphuric acid equipment leaks. This secondary containment area was previously coated with an epoxy that was unable to withstand frequent exposure to corrosive chemicals.

Due to frequent damage to the secondary containment area, the old coating had to be reapplied repeatedly which was expensive, time consuming, and unsafe for employees. This client was in need of an industrial strength epoxy coating that would withstand consistent chemical exposure, limiting time spent on maintenance repairs.

Solution

Devcon Epoxy Concrete Sealer and Devcon Epoxy Coat 7000 AR were selected due to their ability to withstand severe acid and chemical attack.

- The secondary containment area was primed and the surface area sandblasted to ensure optimal adhesion of Devcon coatings.

- The flooring was then chemically cleaned to remove all traces of contaminants and neutralize the acidic environment.

- Devcon Epoxy Concrete Sealer was first applied to create a seal to prevent chemicals from degrading the concrete.

- Devcon Epoxy Coat 7000 AR was then applied to provide the required adhesion and resistance to highly concentrated sulphuric acid.

Project Outcome

Highly Durable Coating

Devcon Epoxy Coat 7000 AR is resistant to sulphuric acid in concentrations up to 98% proving its ability to withstand the corrosive nature of the petrochemical manufacturing process. In conjunction with Devcon Epoxy Concrete Sealer, Devcon Epoxy Coat 7000 AR prolongs the life of the secondary containment unit providing a safe, durable solution for this petrochemical plant.

Easy Application in Difficult Environments

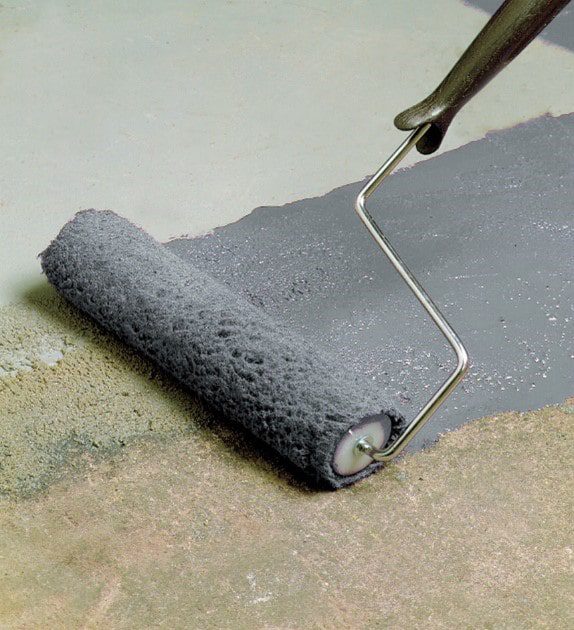

Many times, secondary containment systems can cover an extensive amount of area to surround large industrial equipment. Devcon Epoxy Coat 7000 AR can be seamlessly applied via squeegee and brush roller, to large horizontal and vertical surfaces.

Lowers Repair Costs

A low-grade coating that requires frequent replacement is a short-term solution driving up maintenance repair costs at this petrochemical plant. With Devcon Epoxy Coat 7000 AR this industrial strength epoxy coating is a highly durable solution lowering maintenance costs in the long run by limiting the amount of time spent on repairs.

Devcon Epoxy Concrete Sealer acts as an excellent primer and sealant before application of Devcon Epoxy Coat 7000 AR. In utilizing these two products, this concrete containment area is well equipped to resist chemical corrosion and operate safely.