Problem

A large Crude Oil Refinery uses a common Desalting process to remove salt & impurities from the oil prior to the refining process. This aggressive desalination process utilizes electrostatic coalescence to dissolve the salt. This process occurs in a welded tank which typically is coated to protect the weld seams from damage over a six-year scheduled maintenance cycle.

The customer was coating the tanks with a competitive product that failed well prior to the desired life cycle and schedule. As a result, the customer had damage to the tank weld seams.

Process Conditions

• Temperature: 248° – 266°F (120° – 130°C)

• Pressure: 145 – 174 psi (10 – 12 bar)

• Electricity: 1,000 V/AC with changing polarity

• Life expectancy: 6 years

• Tank wall area: 1600 ft² (150 m²)

Solution

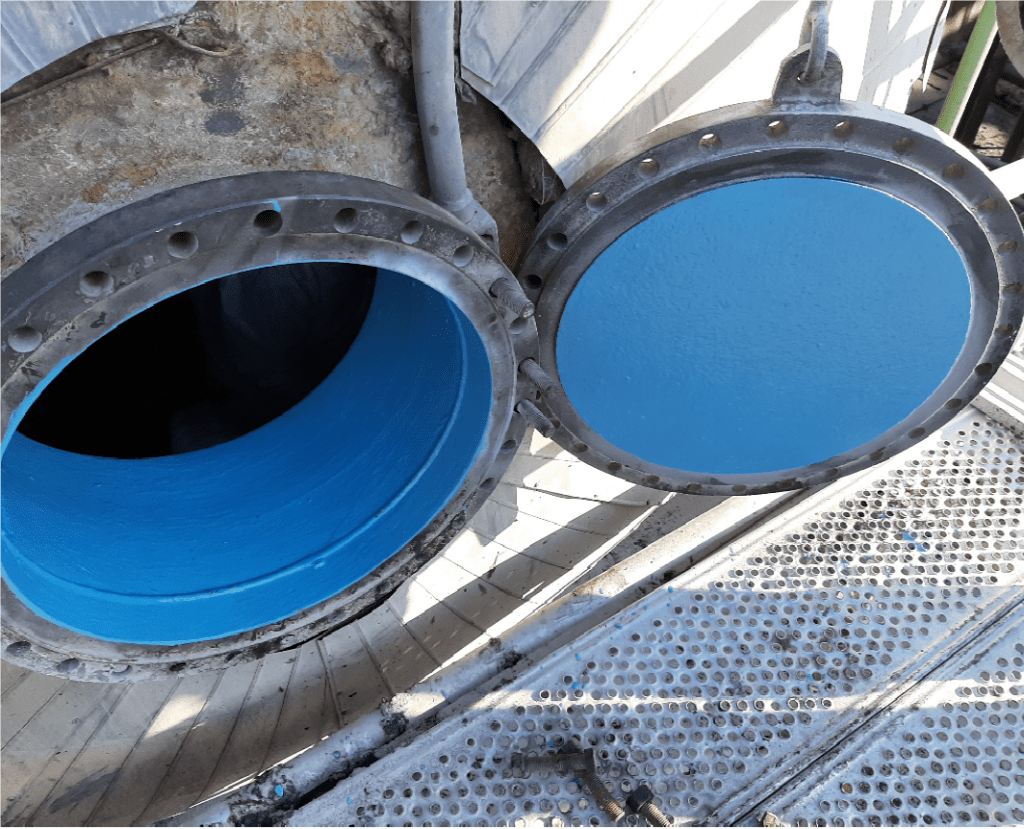

In 2015, the tank was taken out of service, the competitive product removed, sandblasted, and the weld seams repaired. The tank was then coated with 2 layers of Devcon® Brushable Ceramic Blue coating at 600 microns (0.6 mm) and returned to operations.

In 2021, at the end of the scheduled 6-year life cycle maintenance, the tank was inspected, and it was found that although the Brushable Ceramic had changed to a black color, the coating remained intact and providing protection to the tank & weld seams.

A full inspection revealed minor damage to the coatings, but these were in difficult to reach areas such as the manhole covers. The failures identified were far less than the customer’s target 10% failure rate thereby meeting their expectations. As a result,

they reapplied the Devcon Brushable Ceramic coating and returned the tank back to service.

Project Outcome

Devcon Brushable Ceramic Blue Coating effectively protected the refinery desalting tank during the harsh electrostatic coalescence process, thereby preventing damage to the weld seams.

Highly Durable Coating

• Devcon Brushable Ceramic Blue Coating performed better than the competition, outlasting the life cycle requirement; less than 10% of the coating showed damage from the process.

• The coating, on inspection, showed no damage to the weld seams.

Lower Repair Costs

• Weld seams repair is costly and requires specialized inspections. By coating the tank with Devcon Brushable Ceramic Coating, the seams were protected from damage.

• Protecting the weld seams from damage shortens the tank downtime by eliminating repairs and returns the process tank back to operation quickly.

Easy & Safe to Apply

• Devcon Brushable Ceramic Coating is easy to apply and does not require the use of a respirator since the product is 100% solids. This reduces the need for any additional ventilation for an enclosed tank repair.

• Protecting the weld seams eliminates the need for a hot work repair in an enclosed space thereby minimizing hazardous work conditions and providing a safer repair & coating solution.

Devcon Brushable Ceramic Coating provides long-lasting protection in harsh environments withstanding numerous years of continual use. Protect your equipment, extend the life, and minimize future hazardous maintenance cycles with Devcon wear-resistant coatings.