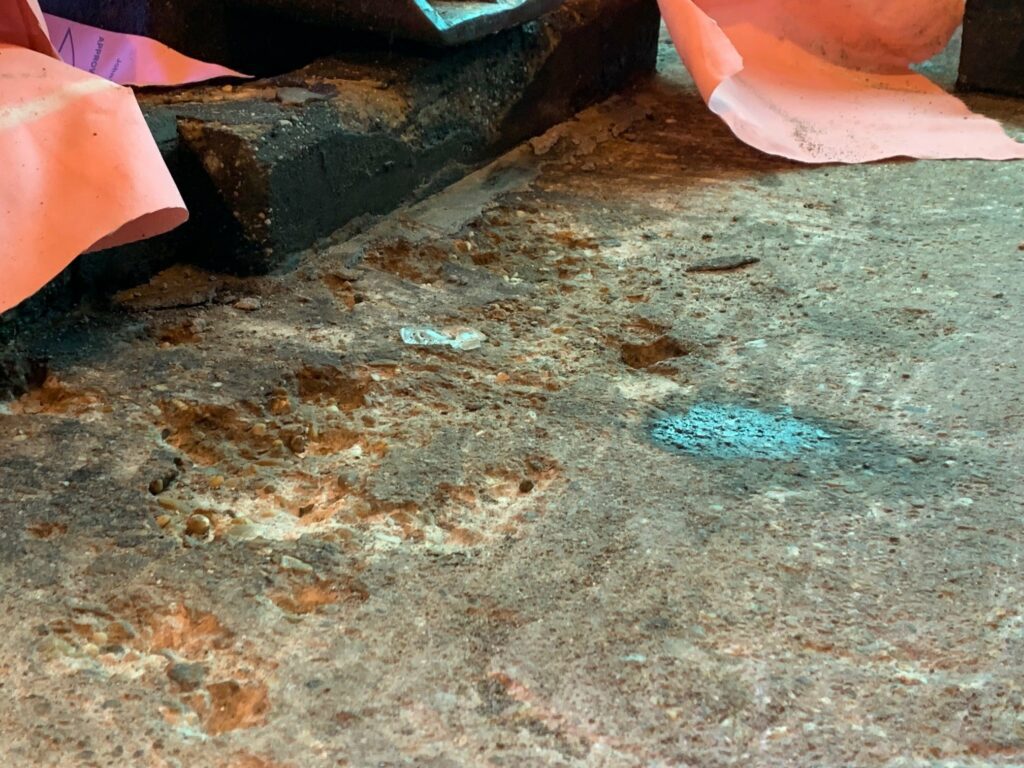

A global petrochemical manufacturer was experiencing high levels of wear and tear in their manufacturing facility, specifically, flooring. Not only was wear caused from common production processes but also from severe chemical attack resulting from alkaline contaminated water.

With the flooring badly damaged, the customer faced potential safety hazards, disruption in plant operations, and structural damage to the facility itself. The customer needed an epoxy system able to repair the damage, refurbish the area, and withstand continuous chemical exposure.

Problem

The challenge in repairing and protecting the badly damaged concrete floor from further chemical attack came from previous failed attempts with inferior concrete floor repair systems. Over the years, various concrete patches were applied, but they all resulted in the eventual detachment from the floor.

The concrete floor became further damaged and developed into a bigger problem and the customer was spending time and resources on something inefficient. With inferior epoxy floor coatings and concrete floor patches not working, the customer decided to rebuild the floor with a high performing, industrial strength epoxy product proven to withstand corrosive chemical attack that wouldn’t have to be repeatedly applied or consume so much time and expense.

Solution

Devcon Floor Patch Resurfacer was selected to address the severe degrading of concrete curbing and flooring due to the caustic environment.

- Floor preparation took three days, removing all the contaminated concrete. Approximately 2” of concrete were removed to expose a healthy suitable base on which to build.

- The concrete floor was pressure washed twice together with a degreaser. Overnight blowers dried the surface and the next morning, Devcon Floor Patch Resurfacer was poured by three teams at different locations, covering the floor space that had been removed.

- 105 kits were applied in 90 minutes.

- After curing for 1 day, an anti-skid paint coating was applied to the concrete floor.

Project Outcome

Quick Application

With limited downtime available, a significant area of flooring to cover, and major pieces of immovable equipment stationed throughout the room, Devcon Floor Patch Resurfacer was successfully applied, allowing the petrochemical manufacturing process to get back up and running after the functional cure time of just 24 hours.

Easy to Use

Devcon Floor Patch Resurfacer is self-leveling requiring little application time and reducing application labor. In just 90 minutes, 105 kits of the epoxy system covered the entire flooring, spreading evenly and consistently despite the layout. As a results, the downtime was reduced to the minimum, adding to the customer’s satisfaction with the project.

Long-Lasting Solution

With floor repairs in place, the plant has successfully installed a more durable solution. Additionally, the industrial strength epoxy coating offers a long-term solution reducing repair frequency and maintenance costs.

Before Repair

After Repair