Problem

A ship in Northern European waters faced severe corrosion on a 1.5‑tonne rudder stock, a critical steering component exposed to harsh Baltic conditions. During dry-dock, inspection revealed advanced degradation, including localized pitting, surface loss, and material weakening. Left untreated, these issues could compromise structural integrity, increase bearing friction, misalign the steering system, and threaten maneuverability and safety.

Historically, partial cleaning and temporary coating touch-ups during dry-dock or localized welding and metal inserts were used. These methods had major limitations: Welding introduced heat distortion and residual stresses, spot repairs offered only short-term relief, and traditional coatings lacked reinforcement for immersion service. Replacement was an option but costly, time-consuming, and requiring specialized machining.

Operationally, these shortcomings meant 1-2 extra dry-dock days per docking, 20-30 man hours for temporary repairs, and persistent risk of unplanned downtime. With corrosion accelerating, the shipowner needed a durable, structurally reinforcing, geometrically precise solution that could be applied within a tight dry-dock window – eliminating recurring corrective work and reducing long-term maintenance costs.

Solution

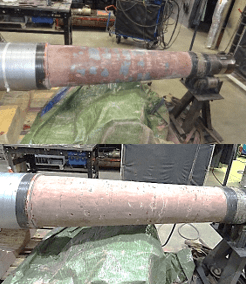

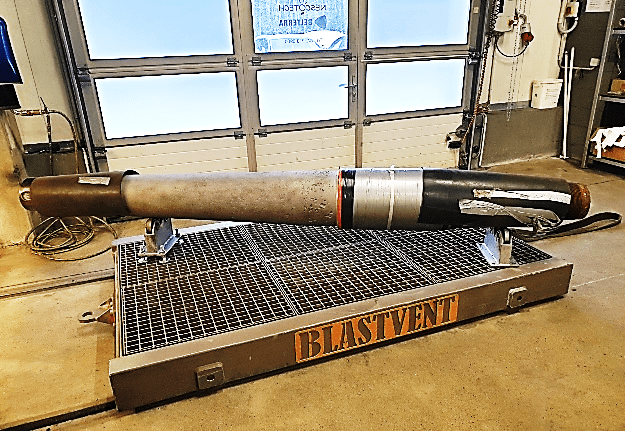

Customer workflow: Full steering disassembly in dry-dock, stock removal, inspection, transfer to workshop for blasting, repair, coating, and reinstallation with proper bearing alignment and torquing.

Devcon system:

- Devcon Titanium Putty rebuilds heavy corrosion, restores geometry, and fills cavities.

- Devcon Brushable Ceramic Red (2 coats) first coat reinforced with fiberglass, long-term corrosion resistance, and uniform finish.

Benefits vs. prior methods:

- Titanium Putty: Strong structural rebuild without heat distortion, excellent machinability and controlled film thickness for correct bearing alignment.

- Brushable Ceramic Red: Smoother finish reducing friction, superior immersion and galvanic resistance, reinforced strength with fiberglass – delivering extended protection and reduced maintenance intervals.

Project Outcome

The Devcon repair and coating system delivered a measurable improvement in operational reliability and maintenance efficiency. By restoring and protecting the 1.5‑tonne rudder stock within a tight three-day dry-dock window, the shipowner achieved:

- Extended maintenance interval: Protection cycle extended by 5-7 years, eliminating repeated touch-ups.

- Reduced dry-dock time: Saved 1-2 days per future docking.

- Lower labor costs: Cut 20-30 man-hours per docking.

- Improved reliability: Smooth finish reduced bearing wear and steering risks.

- Avoided costly replacement: Prevented tens of thousands in material and machining costs.

- Enhanced operational confidence: Minimized risk of unplanned off-hire due to steering failures.