Problem

A world leading copper producer experienced damage to their conveyor belt system. Typically, belting was repaired using metal clips. However, these created the additional problem of not only damaging scrapers, but the clip repairs were prone to creating more damage to the belt over time.

In an attempt to mitigate the problem, a rubber coating competitor product was used, only to be found too time consuming. At least 2X the amount of time was consumed applying their method and the time returning the conveyor to service was even longer. However, giving it a fair chance, it was quickly seen that this solution was not durable enough and the rubber coating quickly cracked and fell of where it touched the metal parts. Ultimately, the lack of efficiency, durability and user safety encouraged the customer to search for a solution that met all their requirements and challenges.

Solution

Known for its durability and quick cure time, Devcon R-Flex was selected.

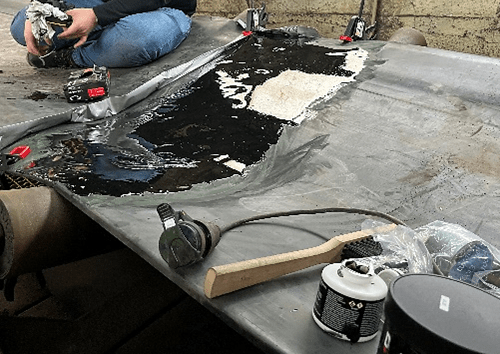

- The surface was cleaned using a soft brush and acetone (around 10cm away from each side of the metal clips), after which the surface was abraded using an abrasive disc, including abrading the metal clips. With a cloth and acetone, the surface was cleaned again to remove residual rubber.

- Next came applying Devcon® Flexane® FL-10 Primer to coat the metallic surface of the clips and Devcon R-Flex Surface Conditioner to coat the rubber surface.

- Mounting protective tape controlled the product flow as the application was on an inclined surface. Then the Devcon R-Flex was poured onto the heavy weight belt and over the metal clips. Using a plastic applicator, the Devcon R-Flex was spread over the belt surface and feathered edges were achieved.

- The Devcon R-Flex chemistry was robust enough to perform the repair in a cool environment. As the ambient temperature was at 59°F / 15°C the Devcon R-Flex could be accelerated with the aid of a portable heater to accelerate the curing process.

Outcome

Proven Superior Performance

The customer’s maintenance and repair team liked the simplicity and speed of the Devcon R-Flex belt repair process. Devcon R-Flex is a self-leveling liquid urethane that quickly and effectively repaired the damage to the SBR conveyor belt and the metal clips without separating or cracking – outperforming the competitor product.

Eliminate Excessive Downtime

With downtime a large concern as production halted, the customer successfully used the Devcon R-Flex synthetic rubber repair system with a small heater to ensure a rapid cure. Even with the belt at an incline and a cool ambient temperature, only 90 minutes were needed to repair the heavy-duty conveyor belt and return it to operation.

Highly Durable Solution

When compared to other brands, Devcon R-Flex succeeds in withstanding abrasive wear in high stress environments. This industrial coating has high adhesion to SBR belts with one of the highest peel resistance strength in the market.

The fast, easy application and longevity of the Devcon R-Flex belt repair system allowed the customer to achieve repair goals in half the time than the competitor product. The repaired belt operates like a new belt.

The Devcon R-Flex SBR belt repair system is known for it's quick cure time & durability