Problem

In many industries, corrosive chemicals are utilized as part of the manufacturing process, which may often lead to wear and damage to the processing equipment. Along with regular inspections, plants must take the necessary measures to limit and contain chemical hazards.

A petrochemical plant utilizes an external holding tank to store large quantities of oil for refining. The plant adds sodium hypochlorite to the oil which to convert crude oil to butane and ethylene compounds.

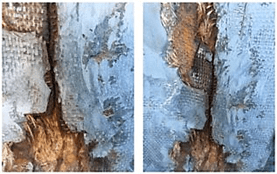

The corrosive nature of sodium hypochlorite caused the lining of the tank to become damaged that could lead to a tank leak if not properly resolved. Immediate repair was needed to limit future spillage. The plant required a fast-acting coating that provided corrosion protection in challenging environments.

Solution

Devcon Devweld 531 and Devcon Flexane 80 Putty were used to stop the potential leak and provide corrosion protection.

- To prime the surface, the repair area was exposed; and damaged and corroded portions of the tank removed.

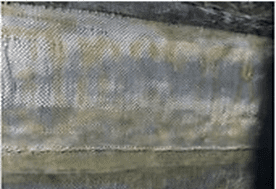

- Devcon Devweld 531 was applied to the surface and fiberglass tape was placed over the damaged area.

- Devcon Devweld 531 provided excellent adhesion to the nylon material coating the tank.

Devcon Flexane 80 Putty was applied to the top of the fiberglass tape. The product was molded by hand with a putty knife to ensuring a smooth surface coating.

Project Outcome

Quick Installation

With Devcon Devweld 531and Devcon Flexane 80 Putty, potential spills of sodium hypochlorite was prevented within just a few hours of the emergency tank repair and the leak effectively repaired.

Highly Durable Coating

The tank needed a coating that would protect the inner lining from severe corrosion. Devcon Flexane 80 Putty and Devweld 531 provided the shell of the equipment with long-term resistance to chemical attack.

Lower Maintenance Costs

Welding holes and cavitation in equipment would require shutdowns and can be very expensive. With Devcon Devweld 531, holes were quickly repaired preventing further chemical leaks. By effectively repairing the external holding tank, the equipment life was prolonged, reducing downtime at the same time saving on maintenance and repair costs.