The high levels of productivity that need to be maintained at a coal plant make unplanned repair work difficult. When the pumps and machinery are taken offline, the equipment downtime costs substantial amounts of time and money.

Problem

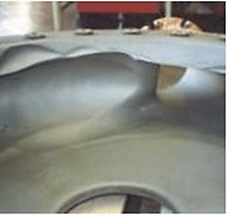

At a coal plant, high solids slurry caused severe abrasive wear to the bottom of their coal ash transfer pump housing. As a result of continuous abrasive wear, this coal plant had to frequently replace the entire pump housing, when required. By fully replacing the pump housing, the coal plant faced high maintenance costs, and a prolonged period of equipment downtime.

Solution

As a cost-effective solution over a full pump housing replacement, the coal plant utilized Devcon Ceramic Repair Compound, Devcon Wear Guard Fine Load, and Devcon Brushable Ceramic coatings.

- The repair area was sandblasted to white metal and the area cleaned with Devcon Cleaner Blend 300, to remove heavy grease and oil deposits on the metal.

- Devcon Ceramic Repair Compound was applied to rebuild wear ring seats, fill holes, and cavitation deeper then 1/8”.

- Devcon Wear Guard Fine Load was applied to a thickness of ½” to 1 ½”, depending on the depth of wear. Acetone was then used to achieve a smooth finish.

Devcon Brushable Ceramic Red & Devcon Brushable Ceramic Blue were individually applied to a total thickness of 30 mils.

Project Outcome

Cost-Effective Solution

- Full replacement of the pump housing would have cost this plant over $30,000. These costs add up as this pump housing is frequently exposed to abrasive wear.

- Devcon repair cost was less than 10% of their typical spend, effectively lowering maintenance and repair costs at this coal plant.

Highly Durable Coatings

- By applying Devcon Wear Guard Fine Load to areas of high wear, this epoxy coating will extend the pump housing life.

- By implementing both Devcon Brushable Ceramic Red and Devcon Brushable Ceramic Blue, the pump housing will be equipped with long-lasting abrasion and chemical protective coatings.

Quick Inspection

By utilizing both Devcon Brushable Ceramic Blue and Red layers, worn-out areas of the pump housing are easily visible as the first color appears in the worn areas.

With Devcon repairs costing less than 10% of the typical $30,000 spend, the coal plant saved approximately $27,000 effectively reducing maintenance cost and prolonging equipment life.